Forget everything you thought you knew about 3D printing. This isn’t about flimsy, layered plastic prototypes that sit on a desk. We’re talking about the real deal: manufacturing-grade, end-use parts that are tough enough for factory floors, precise enough for pharmaceutical equipment, and durable enough to be sold directly to consumers. This is the new era of manufacturing, and it’s powered by professional Industrial 3D Printing Services. If you’re an engineer, product manager, or innovator looking to simplify your supply chain, reduce costs, and accelerate your time to market, you’re in the right place. Let’s dive into how this technology is reshaping production and how a partner like Yuesun3D can turn your ideas into market-ready reality.

Beyond Prototyping: Why End-Use Parts Are a Manufacturing Revolution

For years, 3D printing’s biggest role was rapid prototyping—a quick and dirty way to validate a design before investing in expensive tooling for mass production. But what if you could skip the tooling altogether? What if you could go directly from a digital file to a final, functional product? That’s the power of industrial 3D printing for end-use parts. It’s not just a step in the process; it’s the entire process. This approach slashes lead times from months to weeks or even days. It eliminates the massive upfront cost of injection molds, making low-volume and custom production runs economically viable. It grants unparalleled design freedom, allowing for complex geometries, lightweight structures, and part consolidation that are simply impossible with traditional methods. In short, it’s making manufacturing more agile, intelligent, and accessible.

The Engine of Innovation: Core Technologies for Industrial 3D Printing Services

Not all 3D printing is created equal. The term encompasses a family of technologies, each with its own superpowers. Choosing the right one is critical to the success of your end-use part.

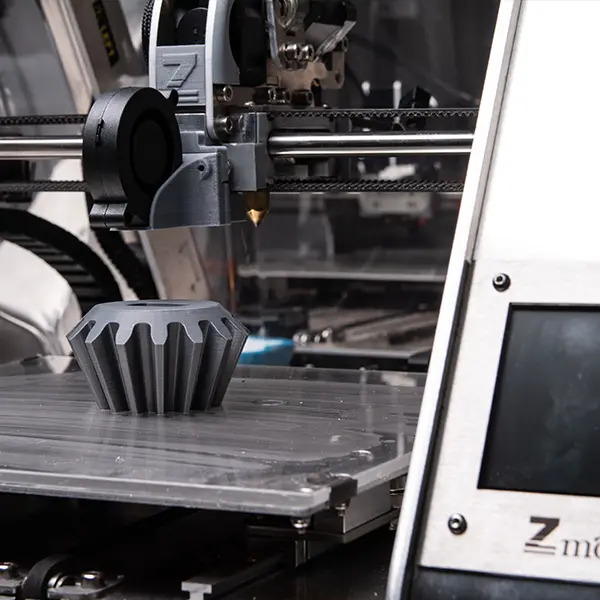

Fused Deposition Modeling (FDM): The Workhorse for Durable, Functional Parts

When you need a part that can take a beating and keep on working, FDM is often the champion. Think of it as a high-tech hot-glue gun that meticulously layers industrial-grade thermoplastics. But this isn’t your desktop hobbyist printer. Industrial 3D Printing Services like Yuesun3D use advanced FDM systems that produce parts with exceptional strength, thermal resistance, and durability. It’s the go-to technology for jigs, fixtures, custom motor mounts, and rugged enclosures. The key advantage? It’s incredibly cost-effective for both prototyping and high-volume 3D printing services, offering a perfect balance of performance and price for demanding applications.

Beyond FDM: A Suite of Advanced Manufacturing Technologies

While FDM is a powerhouse, a full-service partner offers more tools in the toolbox. Technologies like SLA (Stereolithography) and DLP (Digital Light Processing) use lasers or projectors to cure liquid resin into incredibly detailed, smooth parts. This is ideal for applications requiring fine features, tight tolerances, and a superb surface finish, like medical models or intricate components. For parts that need to flex, bend, or absorb impact, materials like TPU (Thermoplastic Polyurethane) are game-changers, allowing for the production of flexible, rubber-like goods. The best Industrial 3D Printing Services will guide you to the perfect technology-material marriage for your specific project.

The Materials Palette: Engineering Thermoplastics for Every Application

The magic isn’t just in the machine; it’s in the material. We’ve moved far beyond basic PLA. Today’s material portfolio for industrial applications is a symphony of engineering-grade polymers. Imagine having over 300 options at your fingertips:

- PLA & ABS: The reliable classics, great for a wide range of consumer and industrial goods.

- PETG: Offers excellent chemical resistance and strength, popular for medical and food-safe applications.

- Nylon (PA): Incredibly strong, durable, and slightly flexible, perfect for functional parts that undergo stress.

- TPU: The flexible filament, essential for gaskets, seals, dampeners, and wearables.

- PC (Polycarbonate): A superstar in impact resistance and high-temperature performance.

- Advanced Composites: Materials infused with carbon fiber, fiberglass, or metal powders for unmatched stiffness and strength-to-weight ratios.

A partner like Yuesun3D doesn’t just offer these materials; they have the expertise to curate the right one to meet your specific demands for rigidity, detail, flexibility, or chemical resistance.

Precision Guaranteed: The Non-Negotiable Role of Quality Control

In manufacturing, “close enough” isn’t good enough. An end-use part must fit, function, and perform exactly as designed, every single time. This is where true industrial services separate themselves from the pack. It’s about a relentless commitment to quality control (QC). How is it done? Through state-of-the-art industrial manufacturing systems that maintain incredibly tight tolerances, often as precise as ±0.05mm. But it doesn’t stop there. Every single batch should undergo a rigorous 100% inspection process. Advanced metrology equipment like coordinate measuring machines (CMM) and calipers verify compliance with your specifications. And the proof? Full inspection reports and material certifications delivered with every order. This isn’t just manufacturing; it’s verifiable, documented reliability.

From 50 to 50,000 Units: Mastering Scalable Production with OEM/ODM Expertise

One of the biggest myths about 3D printing is that it’s only for one-offs. Nothing could be further from the truth. A premier service provider specializes in bridging the gap from your initial 50-unit prototype phase to high-volume manufacturing runs of 50,000+ units. This is the heart of OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services. They handle the entire journey, maintaining unwavering quality, structural integrity, and precise consistency at every stage. With low MOQs (Minimum Order Quantities), you can test the market without massive financial risk and then scale seamlessly as demand grows. It’s a flexible, responsive, and de-risked approach to bringing a product to life.

The Yuesun3D OEM/ODM Process: Your Roadmap from Concept to Global Delivery

So, what does it actually look like to partner with an expert? A transparent, structured process ensures clarity and success from day one.

- Consultation: It starts with a conversation. They discuss your requirements, target market, and ideas. Even a simple sketch is a great starting point.

- Design & Engineering: Their team gets to work, creating optimized 3D models for manufacturing (DFAM) and delivering them for your approval.

- Prototyping: Physical samples are produced and shipped to you within days, not weeks, for hands-on evaluation.

- Mass Production: Upon your confirmation, flexible manufacturing begins, capable of scaling with your needs.

- Quality Control: As discussed, every batch is rigorously inspected, and those valuable reports are provided.

- Global Shipping: They handle the complicated logistics, securely packaging and shipping your order globally with support for FOB (Free On Board) and DDP (Delivered Duty Paid) terms, ensuring a smooth journey to your door.

Conclusion: Partnering for the Future of Manufacturing

The transition to using industrial 3D printing for end-use parts isn’t just a trend; it’s a strategic evolution in how we build things. It represents agility, efficiency, and innovation. By leveraging these services, you gain more than just a supplier; you gain a partner capable of navigating the entire product development lifecycle. Yuesun3D embodies this partnership, offering the technology, material expertise, rigorous quality control, and scalable production necessary to thrive in today’s competitive market. It’s time to move beyond prototyping and start producing. Your supply chain has been waiting for this.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for mass production of end-use parts?

A1: While sample lead times are very short (3-5 days), mass production for end-use parts requires meticulous quality checks. A typical lead time is 10-15 business days, depending on the order size and complexity, ensuring you receive perfect, market-ready products.

Q2: Can you really match the strength and durability of traditionally manufactured parts?

A2: Absolutely. With advanced industrial FDM printing and engineering-grade materials like Nylon, PC, and composites, we produce parts with exceptional mechanical properties, thermal stability, and durability that meet or exceed the requirements for most industrial applications.

Q3: My design is complex. Can 3D printing handle it?

A3: That’s one of its greatest strengths! 3D printing excels at producing complex geometries, internal channels, and lightweight lattice structures that are impossible to mill or mold. Send us your challenge; we’ll help you optimize it for manufacturing.

Q4: How do you ensure consistency across a large production run?

A4: Consistency is guaranteed through our state-of-the-art industrial printers that maintain tight tolerances (±0.1mm) and our rigorous 100% batch inspection process. We measure, document, and verify consistency for every single unit we produce.

Q5: What file format do you need to start a project?

A5: The best format to provide is an STEP file (.step or .stp) as it contains rich, watertight solid data. We also work with other formats like IGES, X_T, and STL. If you only have a concept or sketch, our ODM service can help!