Have you ever had to simplify a brilliant design because it was too “complex” or “expensive” to manufacture? If you’re an engineer or product designer, that feeling is all too familiar. You’re forced to design for manufacturability, shackling your innovation to the limitations of subtractive mills and injection molds. But what if you could flip the script? What if you could manufacture for design? Welcome to the transformative power of Additive Manufacturing Services. This isn’t just a fancy term for 3D printing; it’s a fundamental shift in how we create, allowing us to produce parts with intricate internal channels, organic shapes, and lightweight lattices that were previously impossible. Let’s dive into how this technology is breaking down barriers and how a partner like Yuesun3D can turn your most ambitious designs into tangible reality.

The Design Dilemma: Why Traditional Manufacturing Fails Complex Parts

For centuries, manufacturing has been a game of subtraction and conformity. CNC machining starts with a solid block and carves away material, but it can’t easily create internal complexities. Injection molding requires a custom mold cavity, but undercuts and enclosed channels are a nightmare. These methods impose a tax on creativity. They force you to:

- Break assemblies into multiple parts that need to be assembled later, adding cost, weight, and potential failure points.

- Use more material than necessary, resulting in heavier, less efficient components.

- Abandon optimized organic shapes (like those found in nature) in favor of simpler, easier-to-machine geometries.

This is the old way of thinking. Additive manufacturing services shatter these constraints, offering a paradigm where complexity is free.

The Magic of Layer-by-Layer: How Additive Manufacturing Services Conquer Complexity

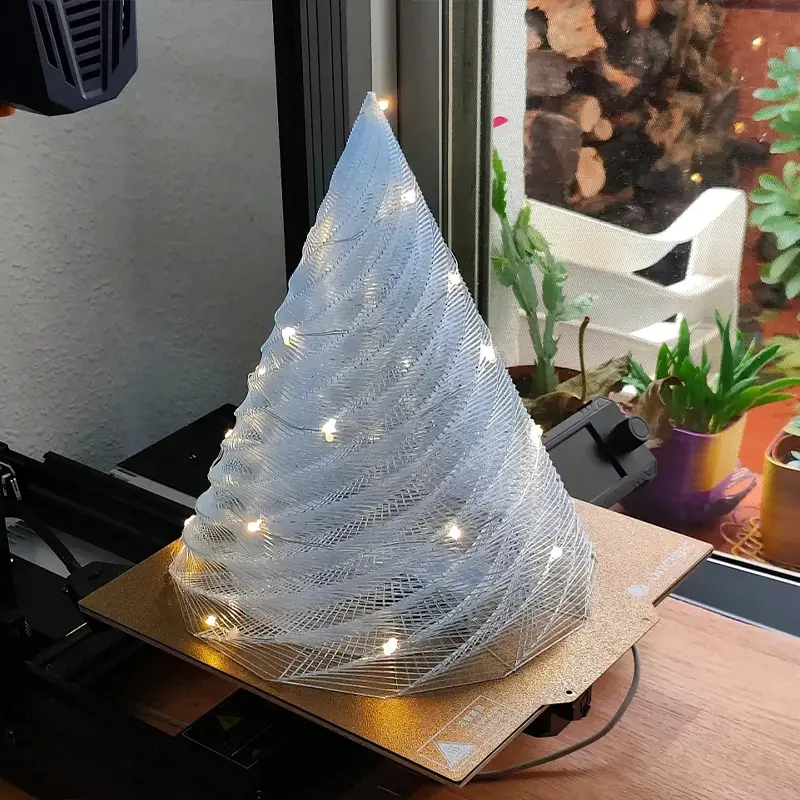

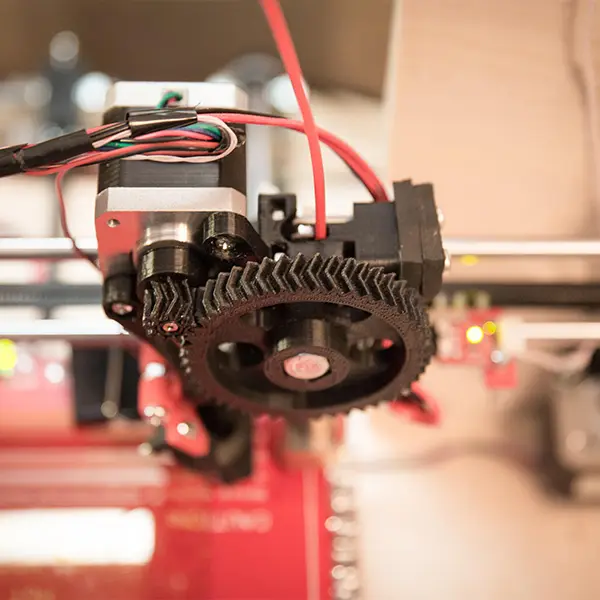

So, how does it work? Think of it like building a structure with incredibly precise Lego blocks. Instead of cutting away, we build up, layer by microscopic layer, directly from a 3D digital model. This layer-wise approach is the key that unlocks a new universe of design.

The Core Technologies Powering Complex Part Production

While several technologies exist, Fused Deposition Modeling (FDM) is a workhorse for functional, durable parts. Industrial-grade FDM, like that perfected by Yuesun3D, uses high-strength thermoplastics to build robust parts layer by layer. Its true power for complexity lies in soluble support structures. These supports hold up overhanging features during printing and are then washed away, revealing breathtaking geometries that defy traditional methods. For ultra-high-detail parts, technologies like SLA and DLP use lasers to cure resin with stunning precision, perfect for intricate features and smooth surfaces.

Generative Design: Letting the Algorithm Create the Impossible

This is where it gets really exciting. Additive manufacturing pairs perfectly with generative design software. You tell the software the constraints of your part—where forces are applied, where it must connect, and how much weight it needs to lose—and the AI generates hundreds of organic, optimized design options. These designs often look like bone structures or alien flora. They are impossibly complex, wildly efficient, and only producible through Additive Manufacturing Services. This isn’t just manufacturing; it’s co-creation with artificial intelligence.

Beyond the Print: The Yuesun3D Advantage for Sophisticated Parts

Creating a complex part isn’t just about having a printer. It’s about having the expertise, materials, and quality control to ensure that the part doesn’t just look good on a screen—it performs flawlessly in the real world.

Material Mastery for Demanding Applications

A complex geometry is useless if it’s made from the wrong material. Yuesun3D’s access to over 300 engineering-grade materials ensures your design isn’t compromised. Need a complex airflow duct that can withstand engine heat? A high-performance nylon or PC is your answer. Designing a custom-fit orthopedic device that needs to be flexible and skin-safe? Medical-grade TPU can do it. This material portfolio is meticulously curated to meet the specific mechanical, thermal, and chemical demands of your application.

Precision Engineering: Ensuring Your Complex Design Matches Reality

What good is a digitally perfect design if the physical part is out of spec? This is where precision manufacturing comes in. Yuesun3D leverages state-of-the-art systems to maintain exceptionally tight tolerances (±0.1mm), ensuring unmatched dimensional accuracy and repeatability. Every single batch undergoes a rigorous 100% quality inspection with advanced metrology equipment. They don’t just send you parts; they send verifiable proof of performance with full inspection reports and material certifications. For complex geometric parts manufacturing, this commitment to quality is non-negotiable.

From CAD to Your Door: A Seamless OEM/ODM Process

Yuesun3D acts as a true partner, offering an integrated OEM/ODM process designed for innovation:

- Consultation: They start by discussing your application, not just your print file.

- Design & Engineering: Their experts perform Design for Additive Manufacturing (DFAM) analysis, optimizing your model for strength and printability.

- Prototyping: Get physical samples in 3-5 days to test form, fit, and function.

- Mass Production: Scale seamlessly from 50 to 50,000+ units without changing processes.

- Global Shipping: They handle the logistics with flexible incoterms (FOB/DDP), delivering anywhere.

This end-to-end expertise ensures a seamless journey from your imagination to a market-ready product.

Real-World Applications: Where Complex Geometries Shine

This isn’t theoretical. Industries are leveraging this right now:

- Aerospace & Automotive: Creating lightweight, strong brackets and ducting with internal lattices, reducing weight and fuel consumption.

- Healthcare: Producing patient-specific surgical guides and implants with porous structures that promote bone ingrowth.

- Industrial Equipment: Manufacturing custom motor mounts and manifolds with integrated cooling channels that can’t be machined.

- Consumer Goods: Designing unique, ergonomic handles and aesthetically stunning home decor items that become a brand’s signature.

Is Your Project a Fit for Additive Manufacturing?

Ask yourself these questions:

- Does my part have complex internal pathways or organic shapes?

- Could I significantly reduce weight without sacrificing strength?

- Am I currently assembling multiple pieces that could be one?

- Do I need custom, low-volume parts without investing in expensive tooling?

If you answered “yes,” you’re sitting on a golden opportunity for innovation.

Conclusion: Stop Designing for Manufacturability, Start Manufacturing Your Design

The era of compromise is over. Additive Manufacturing Services have fundamentally changed the rules of the game, turning design constraints into opportunities for innovation. It allows you to create lighter, stronger, and more efficient parts that unlock new levels of product performance. By partnering with a full-service, quality-driven provider like Yuesun3D, you gain more than a vendor; you gain a catalyst for innovation. They provide the technology, material science, and engineering expertise to bring your most complex ideas to life with confidence. Don’t dumb down your design. Scale up your ambition.

Frequently Asked Questions (FAQs)

Q1: Is additive manufacturing strong enough for functional, end-use parts?

A1: Absolutely. This is the biggest misconception. With industrial-grade equipment and engineering thermoplastics like Nylon, PC, and composites, additively manufactured parts exhibit exceptional strength, durability, and thermal resistance, making them perfectly suited for demanding functional applications in aerospace, automotive, and industrial settings.

Q2: How does the cost of a complex additive part compare to a traditional one?

A2: While the unit cost can be higher, the total cost of ownership is often lower. You save massive amounts on: 1) No tooling costs: Avoid $10,000+ mold fees. 2) Part consolidation: Combine multiple parts into one, saving on assembly. 3) Lightweighting: Use less material and reduce operational costs (e.g., fuel savings). 4) Speed: Get to market faster, which has immense value.

Q3: What’s the best file format to provide for a quote on a complex part?

A3> For parts with complex geometries, the best format is a STEP file (.step or .stp). This format preserves valuable data like curved surfaces and precise geometry, unlike an STL, which approximates surfaces with triangles. This allows for a more accurate analysis and quote.

Q4: Can you add threads, metal inserts, or other features to a 3D printed part?

A4: Yes! This is a key part of the value-add. Yuesun3D offers a full suite of professional finishing services. They can tap threads directly into the plastic, press in certified metal inserts for repeated use, and perform precision painting, electroplating, and seamless assembly to create a fully finished, market-ready product.

Q5: How do I get started if I only have a concept?

A5: That’s the perfect place to start! Yuesun3D’s ODM service is designed for this. Their engineering team can take your concept, sketch, or basic requirements and handle the entire design process, leveraging their expertise in DFAM to create an optimized, manufacturable product from your idea. Just reach out and start the conversation.