So, your project demands more than just a “close enough” part. You need a component that fits perfectly, functions flawlessly, and integrates seamlessly into a larger assembly. You’ve heard about 3D printing, but you’re skeptical. Can it really deliver the precision your work requires? The answer is a resounding yes—but only if you’re working with the right partner. Welcome to the world of industrial High-Precision 3D Printing, where tolerances are measured in microns and consistency is guaranteed. This isn’t hobbyist printing; this is manufacturing-grade accuracy that is reshaping industries. Let’s dive into how it works, why it matters, and how a partner like Yuesun3D can turn your most exacting designs into tangible reality.

Beyond “Good Enough”: Why Micron-Level Precision Matters in Manufacturing

In manufacturing, “close” is only good in horseshoes and hand grenades. For everything else, precision is the difference between a successful product and a costly failure. Why does it matter so much? Imagine a medical device component that’s a hair too wide, preventing a lifesaving mechanism from engaging. Or an aerospace bracket that doesn’t align perfectly, creating a point of stress that could lead to catastrophe. High precision isn’t about being pedantic; it’s about performance, reliability, and safety. It eliminates post-processing headaches, ensures parts fit together without force, and guarantees that your digital design translates perfectly into the physical world. It’s the bedrock of functional, end-use part production.

The Anatomy of Accuracy: How True High-Precision 3D Printing is Achieved

Achieving exceptional tolerances isn’t magic—it’s a science. It’s the culmination of three critical elements working in perfect harmony: cutting-edge technology, advanced materials, and rigorous process control.

The Technology Core: Industrial-Grade Systems & Calibration

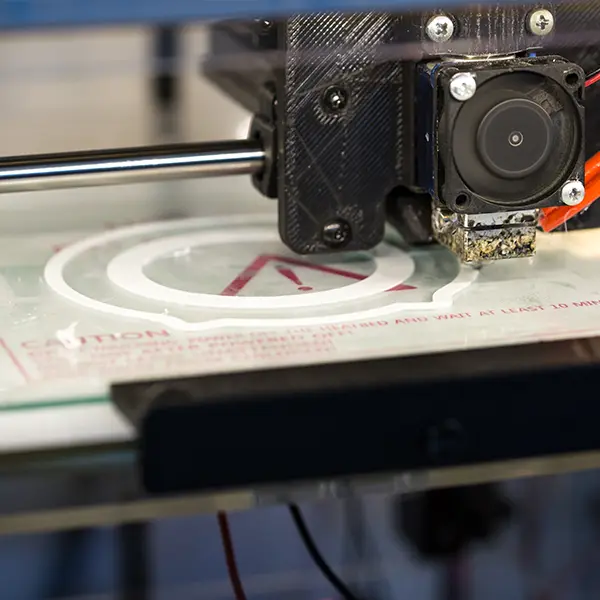

Forget the desktop printers you might be familiar with. High-Precision 3D Printing is achieved with industrial manufacturing systems. These are workhorses built for stability, repeatability, and accuracy. They feature highly calibrated motion systems (think of the rails and belts guiding the print head), advanced extruders that control material flow with incredible accuracy, and thermally stable chambers that prevent the printed material from warping or shrinking during the process. This robust foundation is non-negotiable. It’s the difference between a shaky hand trying to draw a straight line and a CNC plotter executing a perfect vector.

The Material Factor: Engineering Filaments for Dimensional Stability

You can have the best printer in the world, but if you feed it low-quality, inconsistent material, you’ll get low-quality, inconsistent parts. Precision printing requires engineering-grade thermoplastics meticulously formulated for dimensional stability. This means the material undergoes minimal shrinkage or expansion during the printing and cooling process. Brands like Yuesun3D curate a portfolio of over 300 such materials—from high-strength nylons and temperature-resistant PCs to ultra-fine detail resins. Selecting the right material isn’t just about strength or flexibility; it’s about choosing a filament that will behave predictably, layer after layer, to hold the tight tolerances you demand.

The Yuesun3D Standard: A Relentless Pursuit of Perfection (±0.05mm)

Many services claim precision. Yuesun3D documents it. Their commitment is not just a marketing line; it’s an engineered outcome built into every step of their process.

Documented Reliability: The 100% Inspection & Certification Process

This is where true precision is validated. At Yuesun3D, every single batch of parts undergoes a rigorous 100% quality inspection process. This isn’t a casual glance; it’s a metrology-grade examination. They utilize advanced equipment like digital calipers, coordinate measuring machines (CMM), and optical comparators to verify that every critical dimension falls within the exceptionally tight tolerance of ±0.05mm. But they go a crucial step further: they provide full inspection reports and material certifications with every order. You don’t just get parts; you get verifiable, documented proof of their precision and quality. This commitment to high-tolerance 3D printing services is what separates professional manufacturing from amateur printing.

From Prototype to Production: Consistency at Any Volume

Precision is easy to claim for a one-off prototype. The real challenge is maintaining that precision across a production run of 10,000 units. Yuesun3D’s systems and processes are designed for seamless scaling. The same rigorous calibration, material handling, and inspection protocols that ensure accuracy for a 50-unit prototype run are applied to high-volume orders of 50,000+ units. This unwavering commitment ensures unmatched dimensional accuracy and repeatability, whether you’re testing a design or fulfilling a massive bulk order. Your first part and your ten-thousandth part will be functionally identical.

The Real-World Impact: Applications Where Precision is Non-Negotiable

This level of accuracy isn’t a luxury; it’s a necessity in countless advanced applications:

- Medical & Dental: Surgical guides, prosthetics, and custom implants require perfect fits for patient safety and procedural success.

- Aerospace & Automotive: Lightweight components, engine parts, and custom ducting must fit perfectly in complex assemblies under extreme stress and temperature.

- Electronics: Custom housings, connectors, and jigs for PCB assembly demand precise tolerances to protect sensitive components.

- Industrial Machinery: Functional prototypes and end-use parts like gears, motor mounts, and fluidic connectors rely on precision to avoid downtime and ensure operational efficiency.

Partnering for Precision: Is High-Tolerance 3D Printing Right for Your Project?

Ask yourself these questions about your next project:

- Does my part need to interface with other components in a larger assembly?

- Is functional performance more important than just aesthetic appearance?

- Would a failure due to a dimensional inaccuracy be costly or dangerous?

- Am I currently using traditional machining to achieve tolerances that could be met with additive manufacturing?

If you answered “yes,” then your project is a prime candidate for high-precision 3D printing. It’s a cost-effective way to achieve complex, high-accuracy parts without the massive upfront investment of tooling.

Conclusion: Precision Isn’t a Feature, It’s a Foundation

In the world of manufacturing, precision is the invisible foundation upon which reliability, performance, and innovation are built. It’s not just a number on a spec sheet; it’s a promise that your design intent will be perfectly realized in a physical part. By leveraging industrial-grade High-Precision 3D Printing from a partner like Yuesun3D, you gain access to this foundation. You get more than a service; you get a guarantee of quality, backed by cutting-edge technology, material expertise, and an uncompromising inspection process. Don’t compromise on your vision. Demand the precision it deserves and build with confidence.

Frequently Asked Questions (FAQs)

Q1: How does the cost of high-precision 3D printing compare to CNC machining for accurate parts?

A1: For complex, low-to-mid volume parts, high-precision 3D printing is often significantly more cost-effective. You avoid the high hourly machine rates of CNC and, more importantly, the massive cost and time of designing and manufacturing custom jigs and fixtures. For simpler geometries in very high volumes, injection molding may become cheaper, but 3D printing wins on complexity and speed.

Q2: What file format is best for ensuring precision in my final part?

A2> For the highest precision, provide a STEP file (.step or .stp). Unlike STL files, which convert surfaces into triangles, STEP files are a boundary representation (B-Rep) format that preserves exact geometry, including perfect curves and complex surfaces. This allows for a more accurate translation from your CAD model to the printed part.

Q3: Can you achieve different tolerances for different features on the same part?

A3: Absolutely. This is a key part of the design for additive manufacturing (DFAM) consultation. While the printer aims for its best possible tolerance across the entire part, a skilled engineer can design critical features with the precision process in mind, while non-critical areas can have more relaxed tolerances to save on time and cost.

Q4: How do you prevent warping, which is a common cause of dimensional inaccuracy?

A4: Warping is combated through a multi-pronged approach: 1) Using dimensionally stable engineering materials, 2) Utilizing heated build chambers to control the cooling process, 3) Employing sophisticated bed adhesion techniques and specialized build plates, and 4) Strategically orienting the part on the build platform to minimize stress. This is all part of the standard process at a professional service.

Q5: My design has specific critical dimensions. Can you hold even tighter tolerances than ±0.05mm on those?

A5: In many cases, yes. While ±0.05mm is a standard guarantee for overall part accuracy, specific features can often be held to even tighter tolerances through expert design optimization, specialized printing strategies, and dedicated post-processing. Discuss your specific critical features with their engineering team for a feasibility analysis.