How A European Automotive Parts Manufacturer Enhanced Production Efficiency with Custom 3D Printed CNC Fixtures

Introduction

A leading automotive components manufacturer based in Germany approached Yuesun3D with significant production challenges in their machining operations. Their CNC machining centers required specialized fixtures for holding complex-shaped parts during precision machining processes. Traditional fixture solutions were time-consuming to produce and couldn’t adapt quickly to design changes in their rapidly evolving product line. They needed a manufacturing partner who could produce custom fixtures with quick turnaround times while maintaining the precision required for automotive-grade components.

Addressing Production Bottlenecks in Precision Machining

The automotive manufacturer faced increasing pressure to reduce setup times and improve machining accuracy. Their existing fixture solutions required extensive manual adjustment and often caused dimensional variations in machined parts. The company needed fixtures that could securely hold complex geometries without distortion while allowing for quick changeovers between different part numbers. Traditional manufacturing methods were too slow and expensive for their just-in-time production environment.

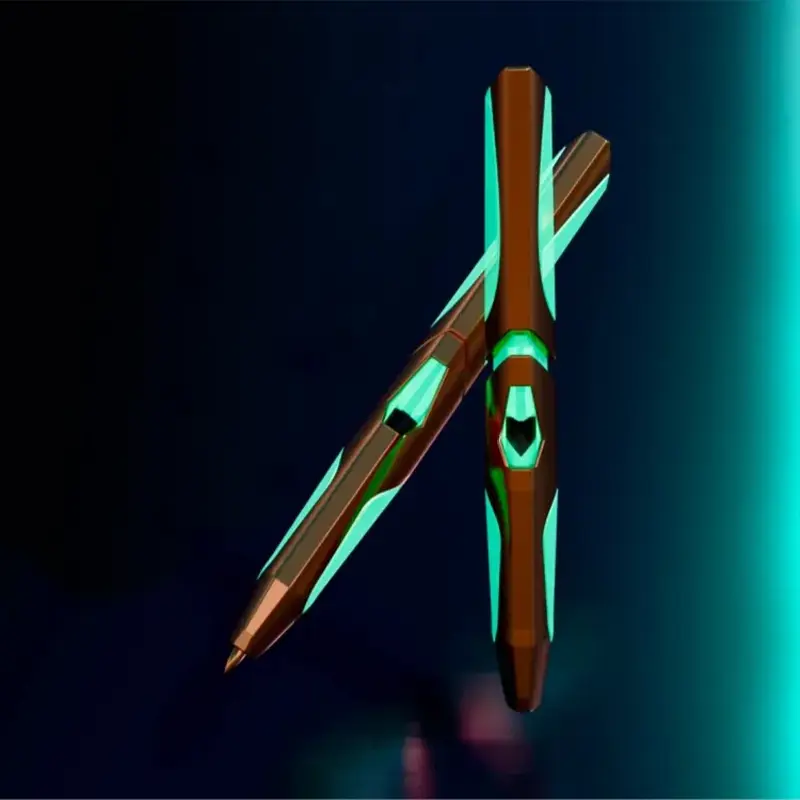

Yuesun3D’s Custom 3D Printed CNC Fixtures offered the ideal solution. The ability to produce complex fixture geometries with integrated clamping features and lightweight structures addressed their core production challenges. The manufacturer was particularly impressed by the rapid prototyping capabilities that allowed for quick design validation before full-scale production.

Technical Collaboration and Precision Engineering

The project involved close collaboration between Yuesun3D’s engineering team and the manufacturer’s production engineers:

- Design Optimization: Developed modular fixture systems with quick-change components that reduced setup time by 60%

- Material Selection: Used high-strength, temperature-resistant polymers that maintained dimensional stability during extended machining operations

- Precision Manufacturing: Achieved positioning accuracy within ±0.02mm, ensuring consistent part quality across production runs

- Weight Reduction: Incorporated lattice structures that reduced fixture weight by 45% while maintaining rigidity and stability

- Rapid Implementation: Delivered complete fixture sets within one week, enabling the manufacturer to meet urgent production schedules

Transformative Impact on Manufacturing Efficiency and Quality

The implementation of Custom 3D Printed CNC Fixtures delivered exceptional results for the automotive manufacturer. Machine utilization rates improved by 35% due to significantly reduced setup times and faster changeovers between production runs. The consistent positioning accuracy of the custom fixtures reduced part rejection rates by 28%, directly improving overall production efficiency.

The manufacturer reported a 40% reduction in fixture costs compared to their previous machined aluminum fixtures, while also eliminating the need for specialized tooling and extended lead times. The lightweight nature of the 3D printed fixtures made them easier to handle and store, improving workplace ergonomics and safety.

Financially, the automotive company achieved annual savings of approximately €250,000 through reduced fixture costs, lower scrap rates, and improved machine utilization. The flexibility of 3D printing also allowed them to quickly adapt to design changes without obsolete inventory concerns.

The success of this partnership has expanded to include other manufacturing aids and tooling components throughout their production facility. The manufacturer is now exploring using Yuesun3D’s capabilities for custom jigs, gauges, and other production accessories.

This case demonstrates how additive manufacturing can transform traditional manufacturing operations, providing both flexibility and precision while significantly reducing costs and lead times.

For manufacturing companies seeking to optimize their production processes with advanced fixture solutions, explore our capabilities in producing custom manufacturing fixtures bulk orders.