How A Robotics Technology Company Enhanced Performance with Custom 3D Printed Gear Assemblies

Introduction

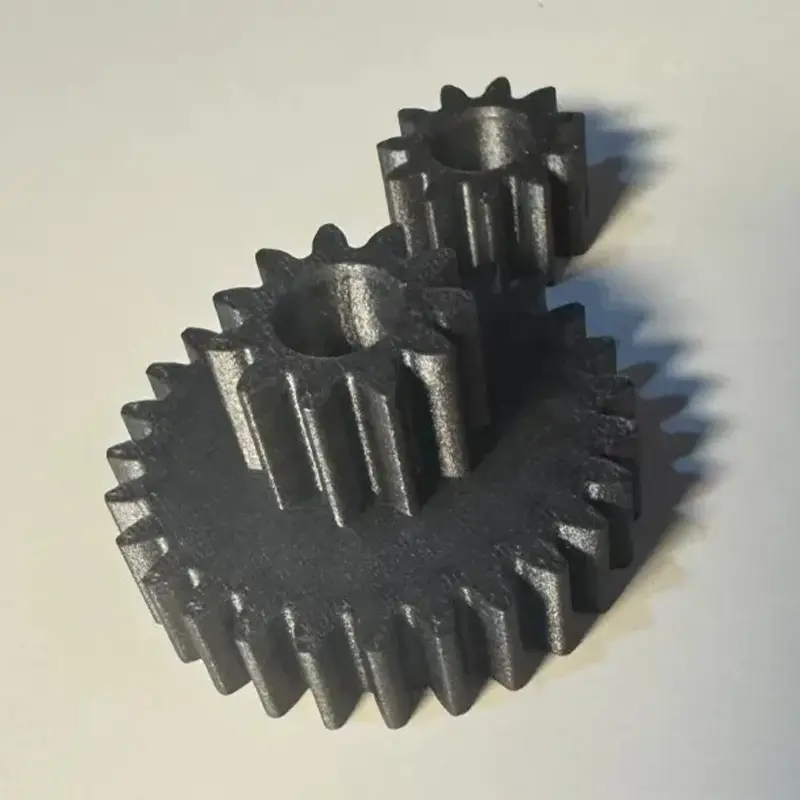

A leading robotics technology company based in Switzerland approached Yuesun3D with a critical design challenge. Their precision robotic arms required custom gear assemblies that combined lightweight construction with exceptional durability and precise torque transmission. Traditional manufacturing methods were proving too expensive and time-consuming for their prototype development and small-batch production needs. They needed a manufacturing partner who could deliver high-precision, custom gear solutions with rapid turnaround times and material options suitable for precision robotic applications.

Identifying Performance Limitations in Robotic Systems

The robotics company’s engineering team discovered that off-the-shelf gear assemblies were limiting their robotic arms’ performance. Standard gears were either too heavy, affecting movement speed and energy efficiency, or not precise enough for the micron-level accuracy required in surgical and manufacturing robotics. The company needed custom solutions that could be optimized for specific torque requirements, weight constraints, and space limitations within their robotic joint mechanisms.

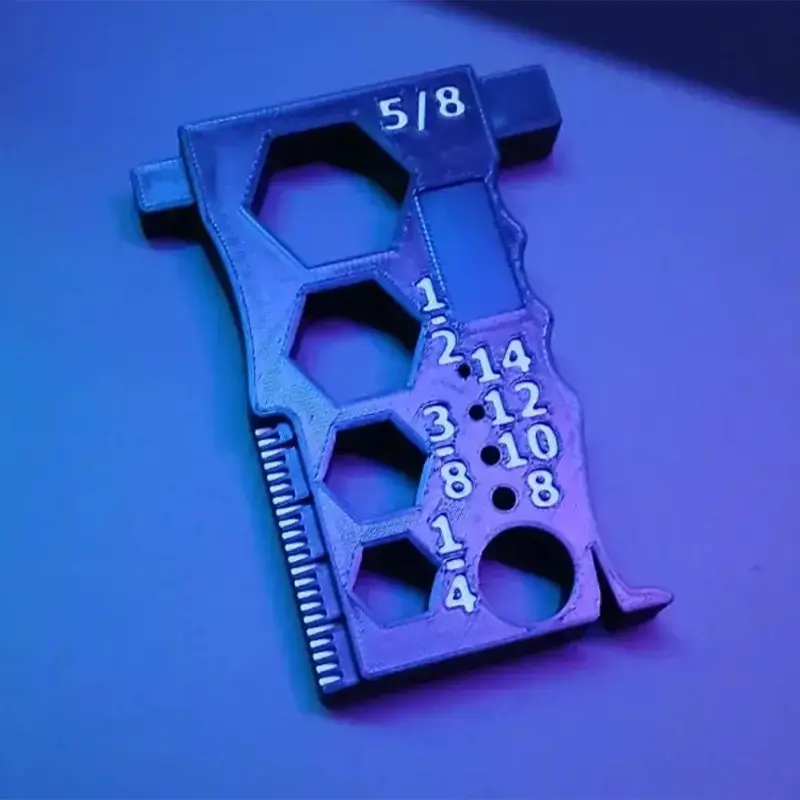

Yuesun3D’s Custom 3D Printed Gear Assemblies offered the ideal solution. The ability to produce complex gear geometries with optimized tooth profiles and lightweight internal structures addressed their core technical requirements. The robotics company was particularly impressed by the material options that provided the perfect balance of strength, wear resistance, and lightweight properties.

Technical Collaboration and Precision Engineering

The project involved close collaboration between Yuesun3D’s engineering team and the robotics company’s design experts:

- Design Optimization: Developed custom gear tooth profiles that minimized backlash and improved power transmission efficiency by 23% compared to standard gears

- Material Selection: Utilized advanced engineering polymers with low friction coefficients and excellent wear resistance, specifically formulated for precision motion applications

- Weight Reduction: Incorporated lattice structures within the gear bodies, reducing weight by 35% while maintaining strength and stiffness

- Precision Manufacturing: Achieved gear meshing tolerances within ±0.05mm, ensuring smooth operation and minimal vibration in high-speed applications

- Rapid Prototyping: Delivered functional prototypes within 72 hours, enabling the robotics company to test and iterate designs quickly

Transformative Impact on Robotic Performance

The custom 3D printed gear assemblies greatly improved the robotics company’s products. Their robotic arms achieved 30% faster movement speeds. This resulted from reduced inertia via lightweight gears. Positioning accuracy was maintained within 5 microns. The custom gears also enabled more compact joint designs. This allowed for greater flexibility and range of motion.

The company reported a 40% reduction in development time for new robotic models, as they could rapidly prototype and test custom gear solutions without waiting for traditional manufacturing lead times. This accelerated time-to-market provided a significant competitive advantage in the rapidly evolving robotics industry.

From a financial perspective, the robotics company achieved 25% cost savings on gear production compared to traditional machining methods, while also reducing inventory costs through on-demand manufacturing. The improved gear performance also led to longer maintenance intervals and reduced warranty claims.

The success of this partnership has expanded to include all gear-driven components in the company’s product line. They are now exploring using Yuesun3D’s capabilities for other precision motion components and custom transmission systems.

This case demonstrates how additive manufacturing can transform precision component production in high-tech industries, enabling performance optimization that was previously impossible with traditional manufacturing methods.

For robotics companies and precision equipment manufacturers seeking to enhance their mechanical systems, explore our capabilities in producing custom industrial gear assemblies bulk orders.