How A European Automotive Service Chain Enhanced Technician Efficiency with Custom 3D Printed Socket Sizing Tools

Introduction

A major automotive service chain with over 300 locations across Germany and Scandinavia approached Yuesun3D with a operational challenge. Their technicians were experiencing efficiency losses and occasional errors in socket selection during rapid repair operations. The existing identification methods were time-consuming and led to workplace frustration, particularly for newer technicians. They needed a solution that would streamline tool selection while maintaining the durability required in professional automotive environments.

Identifying Efficiency Gaps in Automotive Repair Operations

The service chain’s management conducted time-motion studies that revealed technicians spent significant time identifying correct socket sizes. This was particularly problematic during peak service hours and for complex repairs requiring multiple socket changes. Their existing solutions included printed charts that became soiled quickly and digital apps that were impractical in greasy workshop environments.

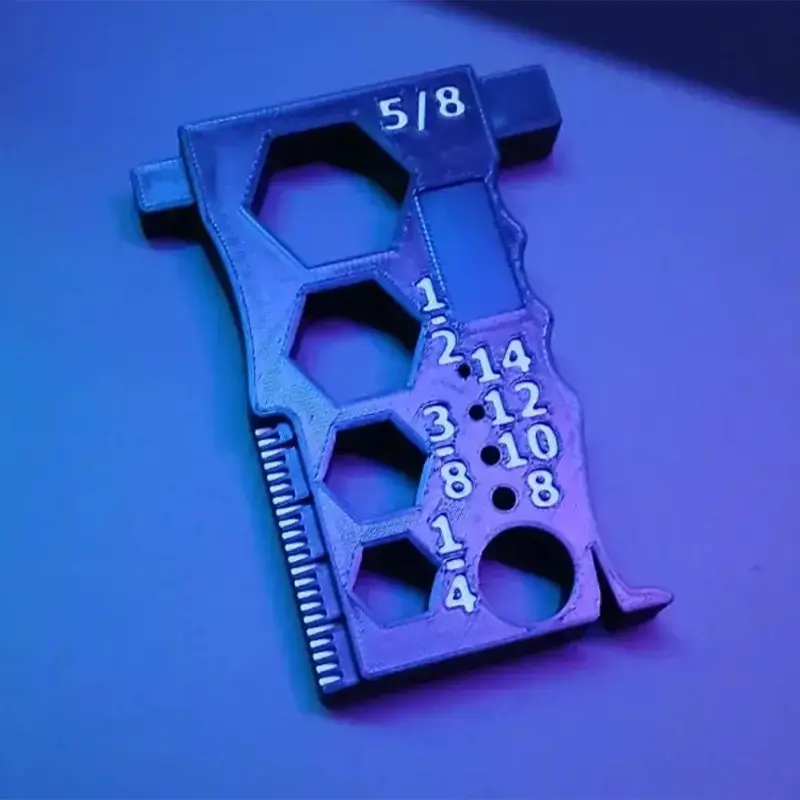

Yuesun3D’s Custom 3D Printed Socket Sizing Tool presented an ideal solution. The combination of permanent engraved markings, chemical resistance, and ergonomic design addressed their core operational challenges. The chain was particularly impressed by the customization options that would allow them to create tools specific to their most common repair scenarios.

Collaborative Development and Custom Implementation

The project involved close collaboration between Yuesun3D’s engineering team and the service chain’s senior technicians:

- Design Optimization: Created a tapered design with the most frequently used metric and standard sizes positioned for quickest access. Added thumb indents for secure grip even with oily hands.

- Material Selection: Used chemical-resistant nylon composite that could withstand exposure to automotive fluids, cleaners, and impacts from accidental drops. The material maintained dimensional stability across temperature variations.

- Customization Features: Incorporated the chain’s logo and color scheme into the design. Added specialized size ranges for specific vehicle brands commonly serviced in their facilities.

- Durability Testing: Conducted rigorous testing including exposure to various automotive chemicals, impact resistance tests, and longevity simulations of 10,000+ identification actions.

- Scalable Production: Manufactured and delivered 15,000 units across all locations within a four-week timeframe. Implemented a phased rollout with training materials on optimal usage techniques.

Measurable Operational Improvements and Cost Savings

The implementation of Custom 3D Printed Socket Sizing Tools resulted in immediate operational improvements. The service chain reported a 28% reduction in socket selection time across all locations. Error rates in initial socket selection decreased by 42%, reducing wear on fasteners and tools from incorrect sizing.

Technician satisfaction scores improved significantly, with many reporting reduced frustration during complex repairs. The tools became particularly valuable for training new technicians, accelerating their proficiency in tool identification and selection.

From a financial perspective, the chain achieved a 35% reduction in socket replacement costs due to decreased improper usage. The durability of the 3D printed tools resulted in virtually no replacements needed during the first year of use, unlike their previous solutions.

The success of this implementation led to an expanded partnership with Yuesun3D for other customized workshop tools and organizational solutions. The project demonstrated how 3D printing could solve specific operational challenges in professional automotive environments while delivering significant ROI.

For automotive service companies and industrial operations seeking to improve technician efficiency and reduce errors, explore our capabilities in producing industrial socket sizing tools bulk orders.