Have you ever struggled to find gifts that truly stand out? In a world saturated with mass-produced items that look identical on every shelf, how do you offer something genuinely unique? What if you could provide gifts that carry personal meaning while maintaining the cost-effectiveness of bulk ordering? Welcome to the transformative world of 3D printing gifts, where customization meets scalability in ways that redefine traditional gifting. Whether you’re a corporate buyer needing hundreds of promotional items, an event planner sourcing memorable wedding favors, or a retailer seeking distinctive products, bulk personalized 3D printing offers unprecedented flexibility. This technology has evolved far beyond prototyping to become a viable manufacturing method for creating meaningful, one-of-a-kind items at scale. Let’s explore how this innovative approach can transform your gifting strategy and deliver exceptional value to your business and customers alike.

The Personalization Revolution: Why Custom 3D Printing Gifts Dominate Modern Markets

We’re living through a fundamental shift in consumer preferences that’s rewriting the rules of gifting. The era of generic, one-size-fits-all presents is rapidly fading, replaced by demand for items that carry personal significance and emotional connection. This isn’t just a minor trend—it’s a seismic change in how people perceive value in physical objects. Personalized 3D printing gifts sit perfectly at the intersection of this revolution, offering the scalability businesses need with the customization consumers crave. Unlike traditional manufacturing methods that become prohibitively expensive for custom work, 3D printing maintains consistent costs whether you’re producing one unit or one thousand unique pieces. This economic reality opens up possibilities that simply didn’t exist a few years ago.

Consumer Shift: From Mass-Produced to Meaningful Customization

Today’s consumers increasingly reject impersonal, off-the-shelf products in favor of items that reflect their identity, values, or relationships. This shift is particularly pronounced in the gifting sector, where the story behind a present often matters as much as the item itself. A generic keychain becomes forgettable, but a keychain featuring a company logo customized with the recipient’s name becomes a keepsake. A standard figurine gathers dust, but a miniature replica of someone’s pet becomes a cherished display piece. This desire for meaningful connection through objects represents both a challenge and opportunity for businesses. Those who recognize that modern gifting is about delivering experiences rather than just products position themselves for remarkable success in increasingly competitive markets.

Technology Meets Creativity: How 3D Printing Enables True Personalization

The magic of 3D printing lies in its digital nature—it treats uniqueness as a feature rather than a bug. Traditional manufacturing methods like injection molding require expensive tooling that must be amortized across thousands of identical units to be economical. Any variation requires new tooling, making customization financially impractical at scale. 3D printing completely inverts this model. Since there’s no tooling involved, producing one hundred different designs costs essentially the same as producing one hundred identical items. The “tool” is a digital file that can be modified instantly and cost-free. This fundamental difference enables businesses to offer true personalization without the traditional cost penalties, opening new revenue streams and strengthening customer relationships through gifts that genuinely reflect recipient individuality.

The Wholesale Advantage: Economics of Bulk 3D Printing Gifts

Many businesses initially approach 3D printing with prototyping in mind, overlooking its tremendous potential for cost-effective production at scale. When strategically implemented for bulk orders, 3D printing gifts deliver compelling economic advantages that directly impact your bottom line while elevating your gifting game.

Cost Analysis: How Bulk Orders Slash Per-Unit Pricing

The economics of 3D printing follow a different logic than traditional manufacturing. While injection molding has high upfront costs (tooling) and low per-unit costs, 3D printing has no tooling expenses with moderately higher per-unit costs that decrease significantly with volume. This creates an interesting crossover point where 3D printing becomes competitive—typically between 50-500 units for most items. When you factor in the additional value of customization, the equation becomes even more favorable. Bulk ordering personalized 3D printing gifts transforms the cost structure through material purchasing power, optimized machine time, and streamlined post-processing. The per-unit price drop isn’t linear; it’s logarithmic, meaning doubling your order quantity might reduce costs by 30-40% rather than a simple 50%. This efficiency makes customized 3D printed items increasingly accessible for businesses of all sizes.

Minimum Order Quantities: Finding the Sweet Spot for Your Business

Navigating minimum order quantities (MOQ) represents a critical decision point in your bulk 3D printing strategy. Unlike traditional manufacturing that often requires thousands of units to be viable, 3D printing typically has much lower thresholds—often as few as 50-100 pieces for standard items. This accessibility democratizes custom manufacturing, allowing smaller businesses to compete with larger players. The key is understanding the relationship between quantity, customization level, and price point. Simple customizations like adding names or dates might have minimal MOQ requirements, while complex unique designs per unit might require higher volumes to remain economical. Working with an experienced provider helps identify the optimal balance for your specific application, ensuring you get the customization you need at a quantity that makes financial sense.

Material Selection: Balancing Quality, Durability and Cost

Material choice represents one of the most significant factors in both the cost and quality equation for bulk 3D printing gifts. Standard PLA filament offers the most economical entry point with decent durability for many applications, while ABS provides enhanced strength and temperature resistance at a moderate price increase. PETG strikes an excellent balance between durability and cost, making it ideal for functional items. For premium gifts, materials like nylon composites or metal-infused filaments deliver exceptional quality and perceived value. The key is matching material properties to your gift’s intended use—a decorative office item has different requirements than a child’s toy or outdoor promotional product. Understanding these material characteristics ensures you select the optimal filament that delivers the right user experience without unnecessary cost inflation.

Most Popular 3D Printed Gift Categories for Bulk Orders

The applications for personalized 3D printed gifts span countless industries and use cases, but several categories consistently deliver exceptional results for businesses implementing bulk gifting programs.

Corporate and Promotional Gifts: Branded Items That Get Noticed

Corporate gifting represents a massive market where personalization transforms standard promotional items into meaningful connections. Instead of another generic logo pen that gets discarded, companies can provide customized desk organizers featuring the recipient’s name alongside corporate branding. Sales teams can gift custom trophy replicas of products they’ve sold to major accounts. Conference attendees receive personalized conference-specific souvenirs rather than generic swag. The psychological impact of receiving something made specifically for the individual creates a powerful brand connection that far exceeds the cost differential from mass-produced alternatives. These items become conversation pieces rather than clutter, extending their promotional lifespan and reinforcing brand identity through genuine appreciation rather than forced exposure.

Personal Keepsakes: Custom Figurines and Decorative Items

The keepsake market has embraced 3D printing for its ability to transform memories into physical objects. From miniature replicas of wedding venues for place settings to personalized anniversary sculptures capturing special moments, these items carry emotional weight that standard gifts can’t match. The ability to scan and reproduce meaningful objects—a child’s favorite toy, a pet, a significant location—creates heirloom-quality gifts with personal significance. Volume production makes these items accessible for event planners, photographers, and retailers serving the commemorative market. The combination of emotional resonance and technical feasibility positions 3D printed keepsakes as premium gifting solutions with strong perceived value that justifies higher price points while maintaining reasonable production costs at scale.

Seasonal and Event-Specific Gifts: Timeless Opportunities

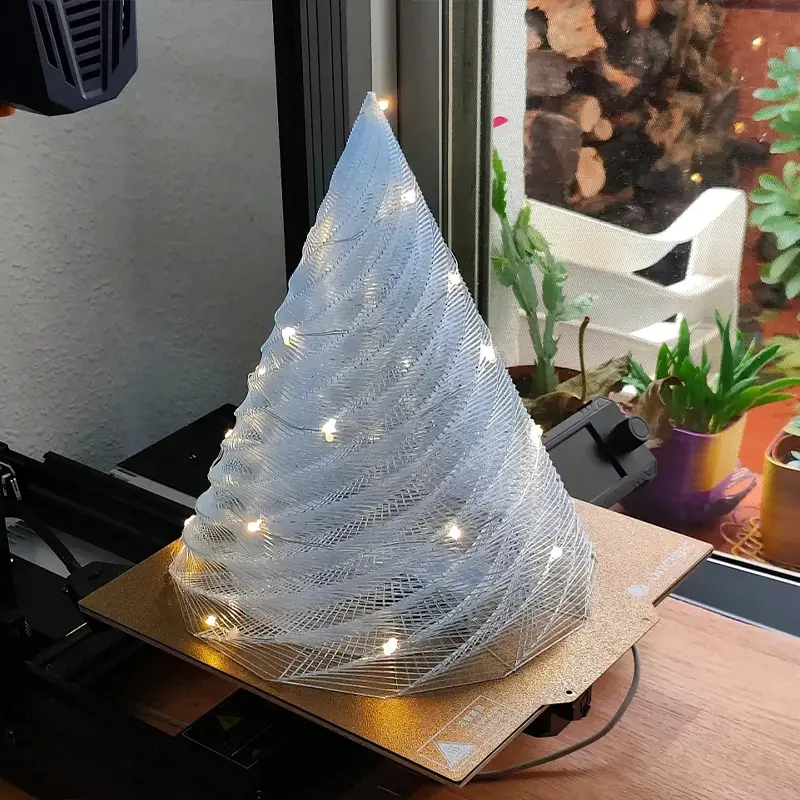

Seasonality creates natural gifting opportunities that benefit tremendously from personalization. Holiday ornaments with family names and dates become annual traditions rather than disposable decorations. Customized Halloween tokens specific to trick-or-treaters create neighborhood legends. Corporate holiday gifts featuring the year and recipient name acknowledge the individual relationship rather than broadcasting generic season’s greetings. The limited-time nature of seasonal items makes them ideal for testing new designs and concepts with lower risk, while the annual recurrence allows for iterative improvement based on previous years’ results. This category demonstrates the perfect marriage of timeliness and timelessness—items that celebrate a specific moment while creating lasting value through personal connection.

The Ordering Process: From Concept to Bulk Delivery

Navigating the journey from initial idea to delivered bulk order seems daunting if you’re new to 3D printing, but modern providers have streamlined this process into a straightforward, predictable workflow.

Step 1: Design and Customization Planning

The process begins with your concept—whether that’s a completely original design or customization of an existing template. Reputable providers offer design services to help translate your idea into a printable file, ensuring technical feasibility while maintaining your creative vision. This stage involves determining the level of personalization—will each item be completely unique, or will there be a base design with variable elements like names or dates? Clear planning during this phase prevents complications later and ensures the final product matches expectations. Many businesses find that starting with a proven design and adding custom elements delivers the best balance of uniqueness and reliability, especially for initial orders.

Step 2: Prototyping and Sample Approval

Before committing to a full production run, requesting samples provides quality assurance and design validation. Modern 3D printing services can typically produce prototypes within days, allowing for rapid iteration based on physical evaluation. This step is crucial for assessing material choice, structural integrity, and aesthetic appeal in the real world. What looks perfect on screen might have proportions that feel wrong in hand, or details that need adjustment for optimal printing. The sample approval process creates a quality benchmark that the full production run must meet, ensuring consistency across all units. This attention to detail separates successful bulk orders from disappointing outcomes, making it worth the minor time investment before full-scale production begins.

Step 3: Production Scaling and Quality Assurance

Once samples receive approval, production scales to your specified quantity. Reputable providers implement rigorous quality control throughout this process, checking dimensions, layer adhesion, and surface finish at regular intervals. The batch nature of 3D printing means issues can be identified and corrected early rather than discovering problems after completing the entire order. This phased approach to quality assurance—catching potential issues during production rather than after completion—saves time, materials, and ensures the final delivery meets specifications. The combination of automated monitoring and human inspection creates a robust system that maintains consistency across hundreds or thousands of units, delivering the reliability businesses require when gifting represents their brand identity.

Material Mastery: Choosing the Right Filaments for Gift Applications

Selecting the appropriate material significantly impacts both the perception and performance of your 3D printed gifts. Understanding material properties ensures optimal results for specific applications.

PLA vs. ABS vs. PETG: Matching Material to Gift Purpose

PLA (Polylactic Acid) remains the most popular filament for gift items due to its ease of printing, vibrant color options, and biodegradable nature. Derived from renewable resources like cornstarch, it offers sufficient durability for decorative items and limited-handling objects. ABS (Acrylonitrile Butadiene Styrene) provides enhanced durability and temperature resistance, making it suitable for functional items that might experience rougher handling or warmer environments. PETG (Polyethylene Terephthalate Glycol) strikes an ideal balance with the printability of PLA and durability approaching ABS, along with excellent layer adhesion that creates stronger parts. For gift applications, material choice should align with expected use—decorative pieces fare well with PLA, while frequently handled items benefit from PETG or ABS.

Specialty Materials: Wood, Metal and Flexible Composites

Beyond standard filaments, specialty materials open unique possibilities for premium gift items. Wood-filled filaments combine PLA with organic fibers, creating prints with authentic wood appearance and scent that can be sanded and stained. Metal-filled filaments containing bronze, copper, or iron particles can be polished and patinaed to create pieces indistinguishable from cast metal. Flexible TPU (Thermoplastic Polyurethane) enables rubber-like items that bend and compress without breaking. These advanced materials command higher price points but deliver exceptional perceived value that justifies the premium for special occasions or high-value relationships. The ability to mix material types within a single order—standard PLA for most items with specialty filaments for VIP gifts—provides flexibility to match material to recipient importance while maintaining consistent production workflows.

The Yuesun3D Advantage: Your Partner in Wholesale 3D Printing Gifts

Navigating the complexities of bulk personalized printing requires more than equipment—it demands expertise, reliability, and a partnership approach. This is where established providers like Yuesun3D deliver significant value through comprehensive solutions that address the entire production lifecycle. Their approach combines industrial-grade equipment with material science knowledge and design optimization expertise to ensure your bulk gift orders meet quality expectations while remaining economically viable. The ability to handle everything from initial concept to final delivery through a single point of contact simplifies logistics while maintaining quality control across the production chain. This end-to-end capability transforms 3D printing from a technical process into a strategic gifting solution that enhances your brand through memorable, personalized items.

Conclusion: Future-Proof Your Gifting Strategy with 3D Printing

The gifting landscape continues evolving toward personalization, experience, and meaning—trends that align perfectly with 3D printing capabilities. Businesses that embrace bulk personalized 3D printing gifts position themselves at the forefront of this shift, offering distinctive items that create emotional connections while maintaining scalable economics. The technology has matured beyond novelty to become a practical manufacturing method capable of delivering both quality and customization at competitive price points. The question is no longer whether 3D printing works for gifting, but how quickly your organization can integrate it into your strategy to gain competitive advantage. The future of gifting is personalized, meaningful, and scalable—exactly what modern 3D printing technology delivers.

Frequently Asked Questions About Bulk 3D Printing Gifts

Q1: How durable are 3D printed gifts compared to traditionally manufactured items?

A1: With proper material selection and quality printing, 3D printed gifts can be exceptionally durable. Engineering-grade materials like PETG and ABS produce items that withstand daily use comparable to injection-molded counterparts. The key is matching material properties to the application—a decorative desk item has different requirements than a functional tool. Post-processing techniques like annealing or epoxy coating can further enhance durability for demanding applications.

Q2: What is the typical lead time for bulk orders of personalized 3D printed gifts?

A2: Lead times vary based on order size and complexity, but most providers deliver bulk orders within 2-4 weeks. This includes design finalization, sample approval, production, and quality control. Rush production may be available for urgent needs, though potentially at a premium. The digital nature of 3D printing eliminates tooling time, significantly compressing timelines compared to traditional manufacturing methods.

Q3: How much customization is possible with bulk 3D printed gifts?

A3: The customization range is virtually unlimited—from simple text personalization to completely unique designs for each recipient. The practical limit depends on your budget and timeline rather than technical constraints. Most businesses balance uniqueness and efficiency by creating a base design with customizable elements like names, dates, or select features that can be varied without complete redesigns for each unit.

Q4: Are there limitations on size for bulk 3D printed items?

A4: Industrial 3D printers accommodate impressive sizes, often up to 12x12x12 inches or larger. For oversized items, designs can be segmented for printing and assembled post-production. Very small items with intricate details may require high-resolution printing technologies. Most gift items fall comfortably within standard printer capabilities, with providers guidance helping optimize designs for successful production at scale.

Q5: How do I ensure color consistency across a large batch of 3D printed gifts?

A5: Reputable providers maintain color consistency through controlled material sourcing, printer calibration, and lighting conditions during production. Using the same filament batch for entire orders prevents subtle variations. For critical color matching, physical color standards can be established during sampling. It’s also wise to request production samples from the beginning, middle, and end of large runs to verify consistency throughout the printing process.