Ever had a game-changing product idea stuck in limbo? You’ve sketched it out, maybe even created a CAD model, but then the cold reality of manufacturing hits. The cost of tooling is astronomical. The minimum order quantities are terrifying. The fear of getting it wrong paralyzes you. Sound familiar? What if you could bypass all of that? What if you could fluidly move from a single prototype to a full production run with the same partner, the same quality, and zero financial drama? Welcome to the transformative power of modern Custom 3D Printed manufacturing. This isn’t just about making a model; it’s about a holistic, agile process that turns your concepts into market-ready products. Let’s explore how this end-to-end approach, perfected by partners like Yuesun3D, is democratizing manufacturing for innovators everywhere.

More Than a Prototype: The New Era of Custom 3D Printing

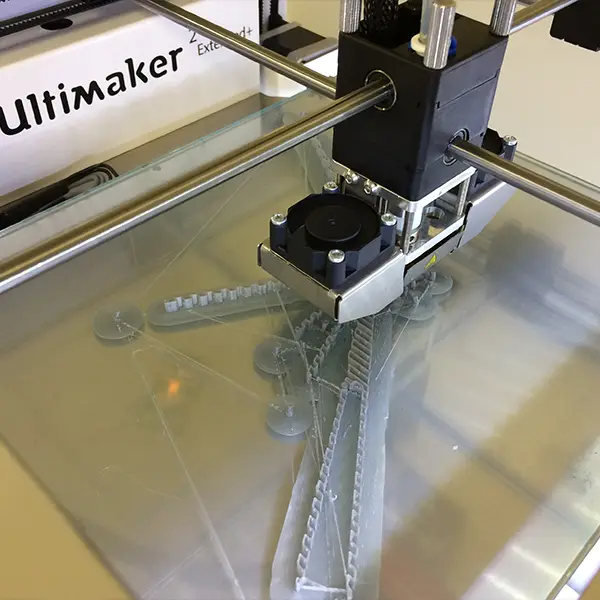

For years, 3D printing was pigeonholed as a tool for rapid prototyping—a quick and dirty way to visualize a design before committing to “real” manufacturing. But that era is over. Today, Custom 3D Printed parts are the final product. Advances in industrial-grade 3D printing technology, like high-performance Fused Deposition Modeling (FDM), and a vast array of engineering-grade materials have blurred the line between prototype and production. The same process that creates a one-off model for functional testing can now be scaled to produce tens of thousands of end-use parts that are durable, precise, and ready for the market. This shift is fundamental: it means you can now design for optimal function without being constrained by the limitations of traditional manufacturing like injection molding.

The Seamless Bridge: Why a Single Partner for Prototyping & Production Wins

The biggest risk in product development isn’t failure; it’s the costly, time-consuming handoff between prototyping and production. Using one vendor for prototypes and another for mass production introduces a world of pain: requalification, communication gaps, and subtle changes that can derail your entire project. The modern solution? A single partner who bridges the entire gap.

The Prototype Phase: Iterate, Test, and Perfect with Agility

This is where ideas become tangible. With a partner like Yuesun3D, you can iterate at lightning speed. Get a physical sample of your design in your hands within 3-5 days. Test its form, fit, and function. Discover a flaw? No problem. tweak the digital file and have a new, improved version in days, not months. This agile process drastically reduces development time and cost, allowing you to perfect your product before committing significant capital. It’s your opportunity to fail fast, learn faster, and arrive at a perfect design without the traditional financial penalties.

The Production Phase: Scale with Uncompromising Consistency

Once your design is locked in, the same technology and meticulous processes used for your prototype are scaled for mass production. This is the critical advantage. There is no “handoff.” There is no re-tooling. The path from 50 units to 50,000 units is seamless. The material, the layer adhesion, the mechanical properties—everything that made your prototype successful is exactly what you get in your production run. This ensures unwavering quality, structural integrity, and precise consistency throughout every stage of your product’s lifecycle. Your supply chain becomes beautifully simple and incredibly reliable.

The Yuesun3D OEM/ODM Process: A Blueprint for Success

How does this seamless journey actually work? It’s built on a structured, transparent, and collaborative OEM/ODM process designed to de-risk your product development.

Stage 1: Consultation & Concept – Your Idea, Our Expertise

It all starts with a conversation. Whether you have detailed CAD files, a rough sketch, or just a concept in your head, Yuesun3D’s team engages to understand your vision, target market, and requirements. This partnership approach ensures we’re aligned on goals from day one.

Stage 2: Design for Manufacturability (DFAM) – Engineering for Reality

This is where the magic of engineering comes in. Their team takes your concept and optimizes it for the additive manufacturing process. They’ll advise on wall thickness, orientation, material selection, and feature detailing to ensure your part is not just printable, but strong, functional, and cost-effective. They deliver the optimized 3D models for your approval, acting as an extension of your own R&D team.

Stage 3: Rapid Prototyping – Hold Your Idea in 3-5 Days

Within days, not weeks, physical samples are produced and shipped to you. This is your chance to touch, feel, test, and validate. It makes the design process real and provides the confidence to move forward.

Stage 4: Scalable Manufacturing – From 50 to 50,000+ Units

Upon your confirmation, they flip the switch to production. With low MOQs starting from just 50 units, you can test market demand without massive financial risk. Their infrastructure is built for flexible scaling, ensuring you can ramp up volume as your business grows, all while maintaining the same impeccable standards.

Stage 5: Rigorous QC & Global Delivery – Your Promise of Perfection

Every single batch undergoes a rigorous 100% quality inspection. Advanced metrology equipment verifies tolerances within ±0.05mm, and full inspection reports provide verifiable proof of quality. Then, they handle the complex global logistics, offering flexible FOB/DDP incoterms to get your finished products anywhere in the world smoothly. This makes low volume manufacturing services accessible and hassle-free.

The Engine of Customization: Technology & Materials for Every Need

The ability to navigate this journey is powered by cutting-edge technology and an unparalleled material library. Yuesun3D’s specialization in industrial FDM technology provides the foundation for creating durable, functional, and cost-effective parts. This is supercharged by a meticulously curated portfolio of over 300 materials—from industrial-grade PLAs and ABS to high-strength Nylons, temperature-resistant PCs, and flexible TPUs. This ensures that whether you require rigidity, intricate detail, or dynamic flexibility, there is a perfect material match for your application. Furthermore, professional finishing services like painting, electroplating, and assembly add the final touch, delivering a truly market-ready product.

Real-World Applications: Custom Parts in Action

This end-to-end process isn’t theoretical; it’s driving innovation across industries:

- Industrial Equipment: Manufacturing robust, custom motor mounts, jigs, fixtures, and replacement parts on demand, reducing machinery downtime.

- Consumer Products & Retail: Creating unique, customized giftware, home decor items, and promotional products without the need for inventory.

- Healthcare: Producing patient-specific medical device prototypes and end-use components that meet rigorous biocompatibility standards.

- Automotive & Aerospace: Fabricating lightweight, complex components for prototyping and interior end-use parts, accelerating design cycles.

Conclusion: Build Boldly, from the First Idea to the Final Unit

The old manufacturing model—with its high barriers, painful handoffs, and massive risk—is obsolete. The future is agile, integrated, and accessible. Custom 3D Printed parts represent more than a technology; they represent a philosophy of building smarter. By partnering with a full-service provider like Yuesun3D, you gain more than a supplier; you gain a strategic ally dedicated to shepherding your idea all the way to the market. You can innovate with courage, scale with confidence, and finally bring your best ideas to life without compromise. The only limit is your imagination.

Frequently Asked Questions (FAQs)

Q1: What is the realistic minimum order quantity for custom 3D printed parts?

A1: The beauty of modern custom 3D printing is its flexibility. While many traditional methods have MOQs in the thousands, services like Yuesun3D offer MOQs starting from just 50 pieces for most projects. This allows for incredibly cost-effective low-volume production and market testing. For truly massive scales of 50,000+, the process remains just as consistent.

Q2: I don’t have a design file. Can you still help me create a custom part?

A2: Absolutely! This is a core part of their ODM (Original Design Manufacturing) service. You can provide a sketch, a photo, or even just a concept description. Their design and engineering team will then develop exclusive, manufacturable 3D models from your concept, handling the entire design process for you.

Q3: How do you ensure the strength and durability of 3D printed parts for end-use?

A3: Strength comes from a combination of industrial-grade technology (not desktop printers) and engineering-grade materials. Using high-performance thermoplastics like Nylon, PC, and ABS, printed on calibrated industrial machines, results in parts with excellent layer adhesion and mechanical properties that are more than capable for most functional, end-use applications.

Q4: What are the key advantages of using one partner for both prototyping and production?

A4: The advantages are huge: 1) Consistency: Your production parts are identical to your approved prototype. 2) Speed: It eliminates the weeks- or months-long requalification process with a new vendor. 3) Cost: It avoids costly tooling transfers and remanufacturing. 4) Simplicity: One point of contact and responsibility for the entire project lifecycle.

Q5: How do I get a quote for my project?

A5: It’s designed to be simple. Reach out to Yuesun3D via their RFQ (Request for Quote) form. Provide your target quantity, a description of the product or its use case, and any design files or sketches you have. Their team will quickly provide a comprehensive, no-obligation quote and expert advice on the best path forward.