What if you could 3D print a single, integrated part that combines the rigidity of a structural bracket with the flexibility of a rubber gasket? Or a prototype that has a soft, comfortable grip seamlessly bonded to a hard, durable body? This isn’t a glimpse into the future; it’s the powerful reality of multi-material FDM printing available today. Many people think of multi-material printing as just a way to use different colors. But for engineers, designers, and manufacturers, it’s a revolutionary capability that allows you to create complex, functional assemblies in a single print job. Ready to move beyond single-material limitations and unlock a new world of design possibilities? Let’s dive into how multi-material FDM is changing the game for product development and manufacturing.

More Than Colors: The Functional Power of Multi-Material FDM

While creating a visually striking two-color model is certainly a benefit, the true power of multi-material FDM printing lies in its ability to combine materials with different mechanical, thermal, and chemical properties. Think of it not as a palette of colors, but as a toolbox of material properties. You can now design a single part that would have previously required multiple manufacturing processes and assembly steps. This means you can embed flexibility where you need it, reinforce areas under stress with specialized composites, and create sophisticated, overhanging geometries with dissolvable support structures. It’s about designing for function, not just form.

How Multi-Material FDM Works: Technology Behind the Magic

So, how does a 3D printer manage to use two or more different materials in one print? The answer lies in advanced hardware and smart material science.

Dual Extrusion Systems: The Engine of Multi-Material Printing

The core of the technology is a printer equipped with two or more independent extruders. Each extruder has its own nozzle and is fed by a separate spool of filament. The printer’s sophisticated software controls which extruder is active at any given moment, laying down different materials in precise locations according to the digital design. This allows for incredibly complex patterns, such as a rigid frame with a flexible interior, or a part that transitions from one material to another at a specific point. This technology is the foundation of professional FDM printing services that can handle complex, multi-material jobs.

Soluble Supports: The Secret to Complex, Clean Designs

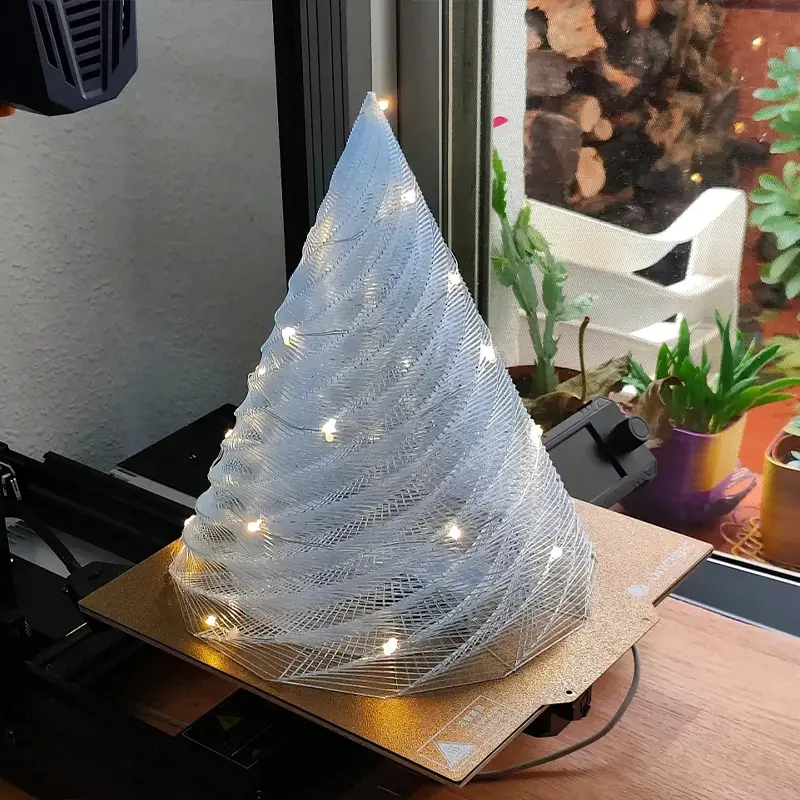

One of the most powerful applications of multi-material printing doesn’t even end up in the final part. By using one extruder for the model material (like ABS or Nylon) and another for a special water-soluble support material (like PVA or HIPS), you can print incredibly complex geometries with massive overhangs and internal cavities. Once the print is complete, you simply place it in water, and the support material dissolves away, leaving a clean, intricate part that would be impossible to produce with traditional break-away supports. This opens up a new level of design freedom.

The Material Combinations That Change Everything

The real magic happens when you start pairing specific materials to achieve unique functional outcomes. Here are some of the most powerful combinations:

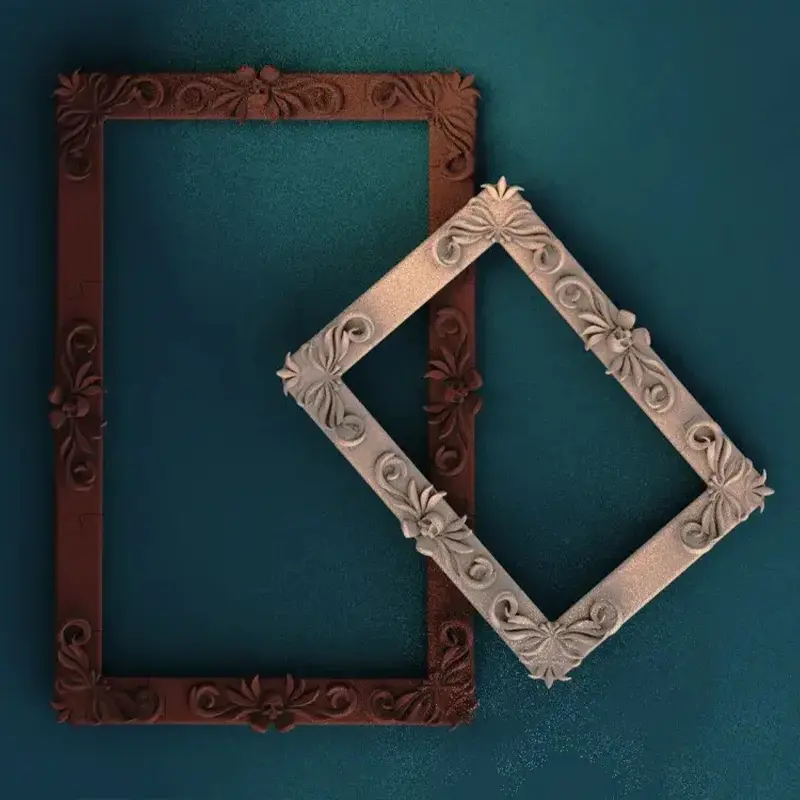

Rigid + Flexible: Creating Integrated Hinges & Seals

Imagine printing a protective case with a living hinge, or an assembly that requires a built-in waterproof seal. By combining a rigid material like ABS or PLA with a flexible thermoplastic polyurethane (TPU), you can create these complex, functional parts in one go. The bond between the materials is created during the printing process, resulting in a strong, integrated component that eliminates the need for separate hinges or gaskets.

Standard + High-Temp: Engineering Advanced Thermal Solutions

For applications involving heat, you can combine a standard, cost-effective material for the main body of a part with a high-temperature resistant material like Polycarbonate (PC) or ABS for specific areas exposed to heat. This is ideal for creating custom jigs for soldering, prototypes for engine compartments, or any part where thermal management is a concern.

Basic Structure + Engineering Composite: Reinforcing Key Areas

Why make the entire part from an expensive carbon-fiber or glass-filled composite when only certain areas need the extra strength? Multi-material printing allows you to use a standard PLA or ABS for the bulk of the part and switch to a reinforced composite material only at the critical stress points. This optimizes both performance and cost.

Real-World Applications: Where Multi-Material Makes the Difference

This technology isn’t just theoretical; it’s solving real challenges across industries:

- Medical Devices: Prototyping ergonomic surgical tools with a rigid body and a soft, non-slip grip.

- Consumer Products: Creating phone cases with a hard outer shell and a soft, shock-absorbing inner layer.

- Automotive: Manufacturing custom grommets and wire guides that have a rigid mounting point and a flexible conduit.

- Robotics: Producing soft grippers for robotic arms that are attached to a rigid base, all as one piece.

Designing for Multi-Material: Best Practices for Success

To get the most out of multi-material FDM, a few design considerations are key:

- Understand Material Compatibility: Not all materials bond well together. It’s crucial to choose materials that will adhere properly during printing.

- Manage the Transition Zone: The interface between two materials is a critical area. Design adequate surface area for a strong bond.

- Leverage Your Software: Use CAD software that allows you to assign different materials to different bodies or regions within a single part file.

Partnering with an experienced manufacturer like Yuesun3D can help you navigate these design challenges effectively.

The Yuesun3D Advantage: Your Partner in Multi-Material Innovation

Successfully executing a complex multi-material print requires more than just a capable machine; it requires expertise. Yuesun3D brings that expertise to the table. Our team understands the nuances of material compatibility, optimal print settings for different combinations, and advanced design techniques to ensure your multi-material parts are not just possible, but perfect. We handle the technical challenges, so you can focus on innovation.

Conclusion: Unlock New Design Possibilities with Multi-Material FDM

Multi-material FDM printing is a transformative technology that breaks down the barriers between different manufacturing processes. It allows you to design and create integrated, highly functional parts that were previously too complex or expensive to produce. By combining different material properties in a single build, you can enhance functionality, simplify assembly, and create truly innovative products. Don’t let your designs be limited by single-material thinking. Explore the possibilities of multi-material FDM and see what you can create.

Frequently Asked Questions (FAQs)

Q1: How strong is the bond between two different materials in a multi-material print?

A1: The bond strength varies depending on the specific materials used. Some combinations, like PLA and TPU, can form a very strong molecular bond during printing. For others, a mechanical interlocking design (like a dovetail) may be recommended for added strength. Consulting with our engineering team during the design phase is the best way to ensure a robust result.

Q2: Can I use more than two materials in a single print?

A2> While dual extrusion (two materials) is the most common and accessible technology, there are printers capable of using three, four, or even more extruders. However, each additional material adds complexity and cost. For most applications, one or two materials are sufficient to achieve the desired functional outcome.

Q3: Are there limitations on the geometry when using soluble supports?

A3> Soluble supports are excellent for complex geometries, but it’s important to ensure that water can flow into and out of all cavities to dissolve the support material completely. Designing small drainage holes can often help with this process.

Q4: Is multi-material FDM printing suitable for end-use parts, or is it mainly for prototyping?

A4> It is absolutely suitable for end-use parts, provided the right engineering-grade materials are selected. For example, a combination of ABS and TPU can create a durable, functional end-use assembly. The key is to match the material properties to the application’s requirements.

Q5: How do I prepare my CAD file for a multi-material print?

A5> The standard method is to create your part as separate “bodies” or “components” within your CAD assembly, with each body assigned to a different material. You then export this as a single file format that preserves this information, such as 3MF. Our technical team can assist you with file preparation guidelines.