What’s the difference between a part that “fits” and a part that fits perfectly? Often, it’s just a few hundred microns—thinner than a human hair. In the world of functional manufacturing, that tiny gap can be the difference between a successful product and a costly failure. While many think of FDM printing as a technology for rough prototypes, the reality is that modern high-precision FDM printing achieves tolerances that rival traditional manufacturing methods. This isn’t about making decorative models; it’s about producing parts with engineering-grade accuracy that snap together, interface seamlessly, and perform reliably. Ready to discover how precision FDM can elevate your projects from “close enough” to “perfect fit”? Let’s dive into the details.

Beyond Hobbyist Printing: What Makes FDM Truly Precise

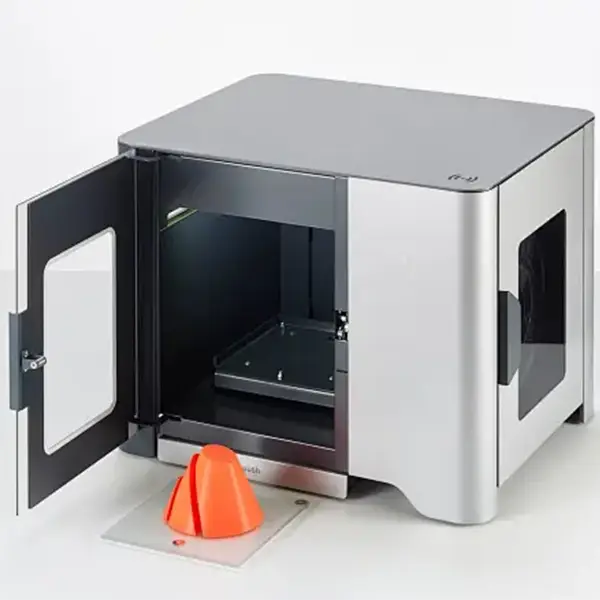

If you’ve only experienced desktop 3D printing, you might think layer lines and slight dimensional drift are just part of the deal. But industrial high-precision FDM printing operates in a completely different league. The key difference lies in the fundamental engineering of the machines and the rigor of the process. Industrial FDM systems are built like machine tools, with rigid frames, precision linear guides, and closed-loop control systems that constantly monitor and correct the position of the print head. They operate in thermally stable, enclosed chambers to prevent warping. This isn’t a hobby; it’s a calibrated manufacturing process designed for one thing: repeatable accuracy.

The Anatomy of Precision: Key Factors in High-Accuracy FDM

Achieving tight tolerances in FDM printing isn’t magic—it’s science. It’s the careful orchestration of three critical elements: hardware, materials, and human expertise.

Industrial-Grade Hardware: The Foundation of Repeatable Accuracy

Precision starts with the machine. Industrial FDM printers feature:

- Rigid Frame Construction: Minimizes vibration and ensures stable movement.

- Precision Linear Motion Systems: High-quality rails and bearings that guide the print head with micron-level accuracy.

- Closed-Loop Control: Sensors that verify the print head’s actual position versus its commanded position, making real-time corrections.

- Thermally Controlled Chambers: Maintain a consistent temperature throughout the build, preventing uneven cooling and warping—the enemy of dimensional accuracy.

This robust hardware foundation is non-negotiable for producing parts that hold tolerances like ±0.1mm batch after batch.

Material Science: Engineering Filaments for Dimensional Stability

You can have the best printer in the world, but if you feed it poor-quality filament, you’ll get poor-quality parts. Precision printing requires engineering-grade thermoplastics formulated for dimensional stability. This means the material has predictable and minimal shrinkage as it cools from a molten state to a solid. Materials like ABS, PC, and certain nylons are excellent for this when properly dried and handled. At Yuesun3D, we meticulously curate our material portfolio and store filaments in climate-controlled environments to ensure they perform consistently, print after print.

The Human Element: Expert Calibration & Process Control

Technology alone isn’t enough. The final ingredient is expert calibration and process control. This includes:

- First-Layer Calibration: Ensuring perfect adhesion and a flat foundation for the entire print.

- Flow Rate & Extrusion Multiplier Tuning: Precisely controlling how much material is deposited.

- Temperature & Speed Optimization: Finding the perfect settings for each specific material and geometry.

This hands-on expertise transforms a capable machine into a precision instrument.

The Tolerance Benchmark: What ±0.1mm Really Means for Your Projects

A tolerance of ±0.1mm (100 microns) isn’t just a number on a spec sheet. It’s a promise of functionality. Here’s what it means in practice:

- Press-Fit Assemblies: Pins and bearings will fit with the intended interference or clearance.

- Threaded Inserts: Holes will be the correct size for inserts to be installed securely.

- Multi-Part Housings: Components will snap together seamlessly without force or gaps.

- Mechanical Assemblies: Gears and moving parts will mesh correctly without binding.

This level of accuracy is sufficient for the vast majority of functional prototypes, jigs, fixtures, and even many end-use parts. It’s the hallmark of a true professional 3D printing service.

Real-World Applications Where Precision FDM Makes the Difference

This isn’t theoretical. Precision FDM is solving real engineering challenges every day:

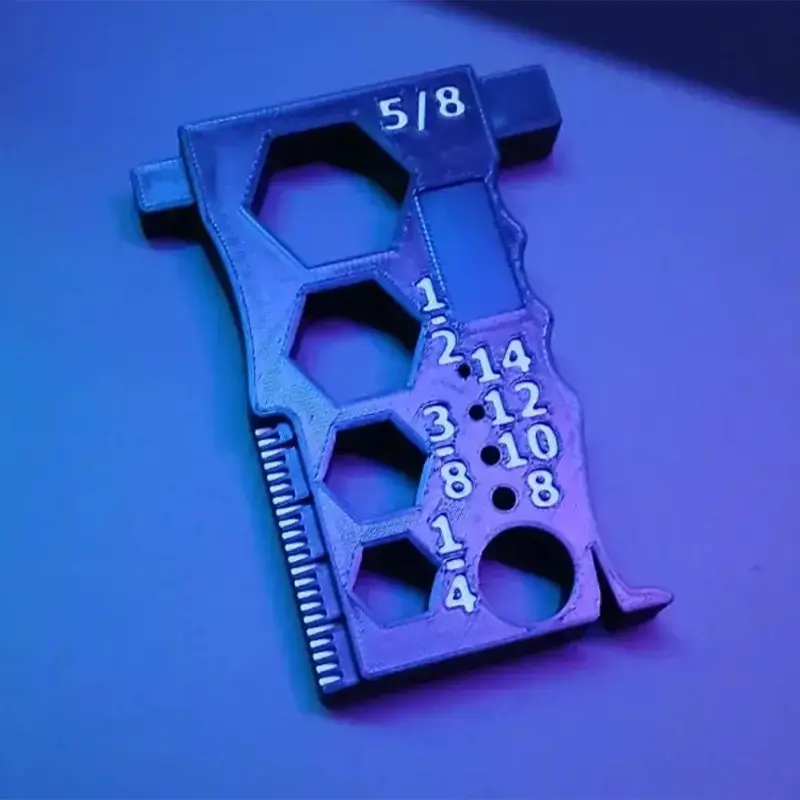

- Custom Jigs & Fixtures: A drilling guide for an aircraft assembly must have bushing holes positioned within a few hundred microns to ensure proper alignment.

- Functional Prototypes: A gearbox housing for a small motor must be dimensionally accurate to ensure the shafts and gears align perfectly for testing.

- Medical Device Components: A surgical guide must fit a specific instrument snugly to ensure procedural accuracy.

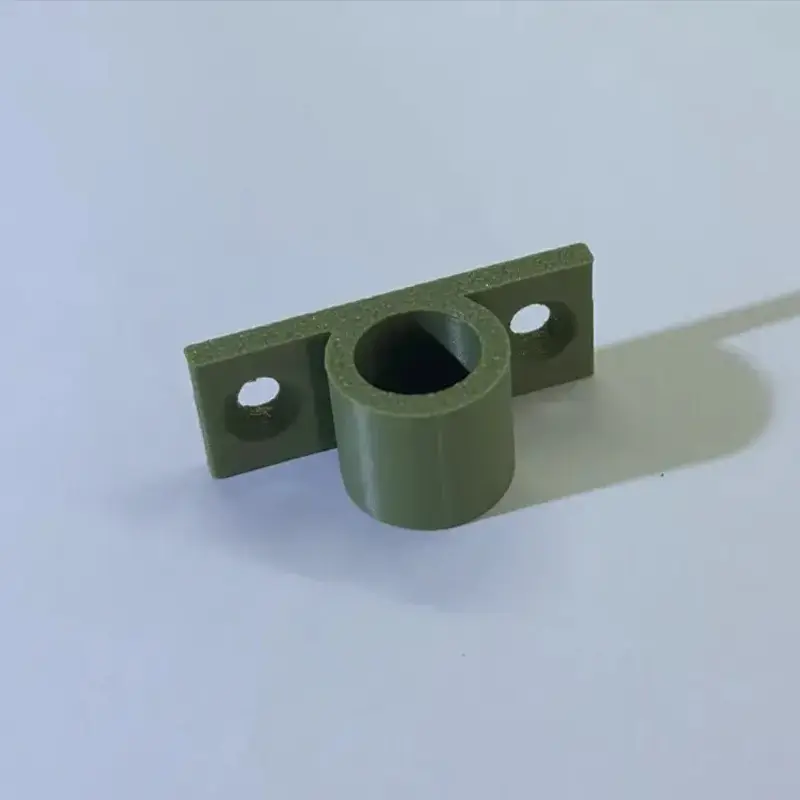

- Electronics Enclosures: A custom case for a PCB must have mounting posts that are the exact right diameter and height for the board to sit flush.

In each case, precision is not a luxury; it’s a requirement for the part to function as intended.

The Yuesun3D Precision Advantage: Our Approach to Guaranteed Accuracy

At Yuesun3D, precision isn’t an accident; it’s a system. Our commitment to accuracy is built into every step:

- Pre-Production Design Analysis: We review your model to identify potential issues that could affect accuracy, such as thin walls or unsupported features.

- Strategic Print Orientation: We orient your part on the build plate to maximize dimensional accuracy on critical features.

- Rigorous In-Process Monitoring: Our technicians monitor prints to ensure they are proceeding flawlessly.

- Post-Production Metrology: We don’t just hope parts are accurate; we verify it. We use digital calipers, micrometers, and other tools to check critical dimensions on every batch, providing documented quality control with inspection reports.

This end-to-end control is how we guarantee that the parts you receive meet your exact specifications, every time.

Conclusion: Precision FDM – When “Close Enough” Isn’t Good Enough

In the world of functional parts and professional manufacturing, “close enough” is the starting point for failure. High-precision FDM printing has evolved into a reliable, accurate, and accessible manufacturing technology that bridges the gap between conceptual design and functional reality. By understanding the factors that drive accuracy—industrial hardware, stable materials, and expert process control—you can leverage this technology to create parts that don’t just look right, but work right. When your project’s success depends on a perfect fit, trust a process built on a foundation of precision.

Frequently Asked Questions (FAQs)

Q1: Can high-precision FDM printing achieve tolerances tighter than ±0.1mm?

A1: While ±0.1mm is a standard and reliable benchmark for most features, it is possible to hold tighter tolerances (e.g., ±0.05mm) on specific, well-designed features. This depends on the part geometry, the specific material, and the print orientation. Discussing your critical features with our engineering team during the quoting process is the best way to achieve optimal results.

Q2: How does the accuracy of FDM compare to CNC machining or injection molding?

A2: CNC machining generally holds the tightest tolerances (often ±0.025mm or better) and produces the best surface finish. Injection molding is also highly accurate. High-precision FDM is incredibly capable for a wide range of applications, but it may not match the absolute pinnacle of CNC accuracy. Its key advantage is the ability to produce complex geometries without tooling, making it highly cost-effective for prototypes and low-to-medium volume production where its level of accuracy is sufficient.

Q3: Do I need to design my parts differently for high-precision FDM compared to other manufacturing methods?

A3: Yes, and this is a key part of our service. Designing for Additive Manufacturing (DFAM) involves considerations like accounting for slight overgrowth on horizontal holes, optimizing orientation for strength and accuracy, and designing clearances for moving parts. Our team can provide DFAM analysis to help optimize your design for the best possible outcome.

Q4: How do you account for the inherent layer lines in FDM when talking about precision?

A4: This is an important distinction. Dimensional accuracy (hitting a specific measurement like 10.00mm) is different from surface finish (the smoothness between layers). A part can be dimensionally very accurate but have a textured surface. For applications requiring smooth surfaces on critical dimensions, we offer post-processing services like machining, sanding, or vapor smoothing to achieve the desired finish while maintaining the underlying accuracy of the part.

Q5: What file format is best for ensuring precision in the final printed part?

A5: For the highest precision, we recommend uploading a STEP file (.step or .stp). This format preserves the design’s precise mathematical geometry. While STL files are common, they approximate surfaces with triangles, which can introduce very minor deviations. For most applications, a high-resolution STL is perfectly adequate, but for ultimate precision, STEP is preferred.