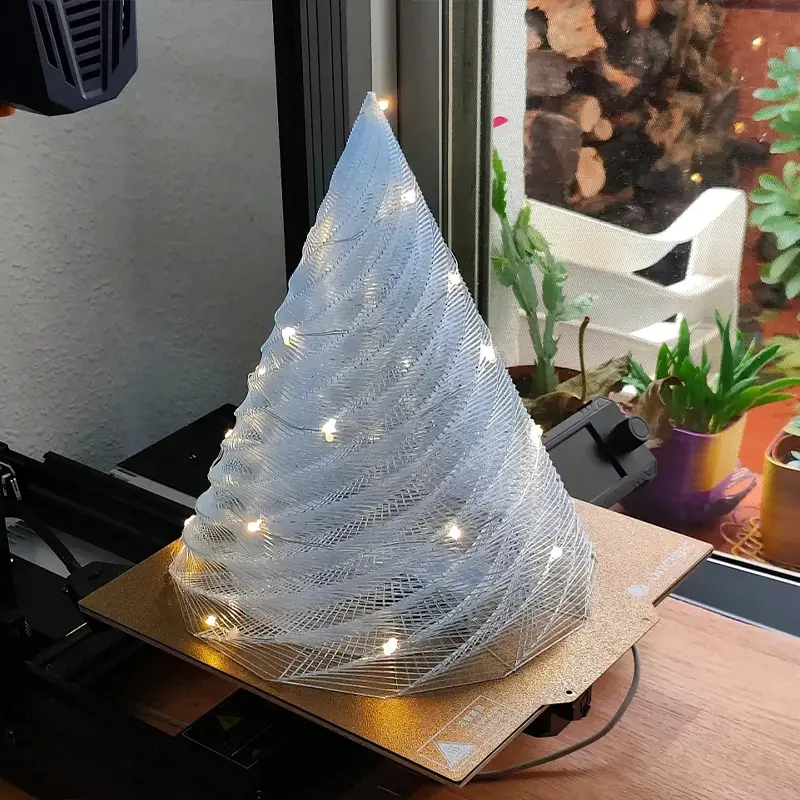

Let’s be honest. When you hear “3D printing,” you might still picture a desktop machine whirring away on a colorful plastic trinket. But what if I told you that the same core technology is now quietly revolutionizing assembly lines, supply chains, and product portfolios for some of the world’s most demanding industries? We’re talking about industrial FDM 3D printing services, and it’s high time we moved it out of the “rapid prototyping” box and into the “strategic manufacturing” category. This isn’t about making one-off models; it’s about building a resilient, adaptable, and surprisingly cost-effective production engine. Ready to see how you can scale your production without the traditional headaches? Let’s dive in.

The Manufacturing Evolution: It’s Not Your Hobbyist’s 3D Printer

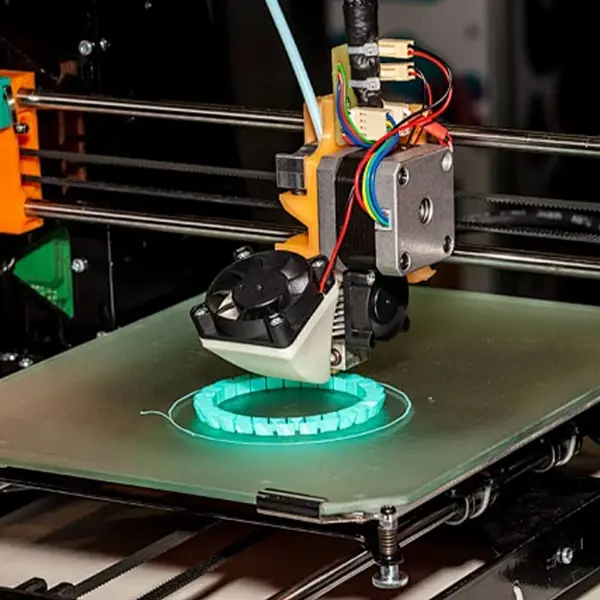

Think of the difference between a bicycle and an 18-wheeler truck. Both have wheels and can get you from A to B, but their purpose, capacity, and reliability are worlds apart. That’s the gap between hobbyist FDM (Fused Deposition Modeling) and its industrial-grade counterpart. Industrial FDM isn’t just a bigger, faster machine. It’s an integrated system built for one thing: consistent, repeatable, and scalable production. We’re talking about enclosed, temperature-controlled chambers that prevent warping, advanced extruders that handle abrasive composites, and sophisticated software that ensures every single part in a batch of 10,000 is identical to the first. This is manufacturing-grade reliability, layer by layer.

The Pillars of Industrial FDM: What Makes it a Production Powerhouse?

So, what are the specific superpowers that make industrial FDM a legitimate choice for scaling production? It boils down to three core pillars that work in harmony.

Unmatched Material Versatility: Engineering-Grade Thermoplastics

This is where the magic truly begins. Unlike many other 3D printing processes, industrial FDM doesn’t limit you to fragile resins. It uses the same robust, proven thermoplastics you find in traditional manufacturing. We’re talking about materials that can take a beating and ask for more. Need incredible strength and heat resistance? Nylon (PA) and Polycarbonate (PC) are your go-to. Need a part that’s stiff and durable? ABS has been the industry standard for decades. What about chemical resistance or specific certifications for aerospace or medical use? There are specialized materials for that, too. This material library means you aren’t just printing a “representation” of a part; you’re manufacturing a functional component with the properties to perform in the real world.

Precision & Repeatability: The ±0.1mm Guarantee for Consistency

Precision is non-negotiable in production. An error of half a millimeter might be acceptable for a prototype, but it’s a disaster on the assembly line. Industrial FDM systems are engineered for exceptional accuracy, maintaining tight tolerances like ±0.1mm across entire production runs. How? It’s a combination of high-resolution motion systems, advanced calibration, and rigorous quality control. Every batch undergoes inspection, and with a partner like Yuesun3D, you receive detailed reports and material certifications. This isn’t just about making parts; it’s about delivering verifiable, documented consistency. You get parts that fit, every single time.

Scalability on Demand: From 50 to 50,000+ Units Without Missing a Beat

This is the killer feature for modern businesses. Traditional manufacturing methods like injection molding have a massive upfront cost (the mold tooling) that only makes sense for huge volumes. What if you only need 500 units to test a market? Or your demand is seasonal? Industrial FDM shines here. The cost per part is relatively linear. There are no expensive molds to amortize. This makes it the ultimate tool for high-volume FDM production of custom parts, low-volume batches, and on-demand manufacturing. You can start with a small order of 50 units to de-risk your launch and then scale seamlessly to thousands as demand grows, all with the same predictable quality and without any retooling costs.

Your Blueprint for Success: Key Applications for Industrial FDM

Okay, the theory sounds great. But where does it actually work in the real world? Here are the most powerful applications where businesses are leveraging industrial FDM right now.

Jigs, Fixtures, and Tooling: The Unsung Heroes of Factory Efficiency

Often the most immediate and high-ROI application. Factories spend a fortune on custom jigs, fixtures, and assembly aids—and they often wait weeks for them. With industrial FDM, you can design and print a custom tool in-house (or through a partner like Yuesun3D) in a matter of days, not months. These tools are lightweight, incredibly durable (using materials like ABS or Nylon), and can be ergonomically optimized. The result? A faster, safer, and more efficient production line with a rapid return on investment.

End-Use Parts: When FDM is the Final Answer

For certain products, FDM is no longer just for prototyping; it’s the final manufacturing method. This is ideal for complex, low-volume parts where traditional methods are too expensive or limiting. Think of custom brackets for specialized machinery, bespoke consumer products, or parts with integrated assemblies that would be impossible to mold. The ability to create complex geometries without tooling, combined with the strength of engineering plastics, makes FDM a perfect final-step solution.

Bridge to Injection Molding: Smart, Low-Risk Market Validation

Planning for a million-unit product? Fantastic. But instead of investing $50,000 in an injection mold before you’ve sold a single item, use industrial FDM as a bridge. You can produce hundreds or even thousands of high-quality, functional units using FDM to validate your market, gather user feedback, and secure pre-orders. Once you have proven demand, you can then confidently invest in the injection mold, drastically reducing your financial risk.

The Yuesun3D Advantage: Your Partner in Scaling with Confidence

Navigating this shift can be daunting. That’s where a specialized partner makes all the difference. Yuesun3D isn’t just a service bureau; they are manufacturing consultants who specialize in scaling production with industrial FDM. Their expertise in Design for Additive Manufacturing (DFAM) means they can optimize your part for strength, cost, and printability from the very beginning. With a focus on engineering-grade materials and a commitment to tight tolerances and rigorous QC, they ensure that your small batch or large-scale run is delivered with the reliability your business depends on. They handle the complex manufacturing and global logistics, allowing you to focus on what you do best: growing your business.

Conclusion: Industrial FDM – Your Strategic Lever for Agile Manufacturing

The message is clear: industrial FDM 3D printing has graduated. It’s a mature, reliable, and strategically vital manufacturing technology that offers unparalleled agility. It empowers you to innovate faster, respond to market changes more effectively, and manage your production capital more wisely. In a world that demands flexibility and speed, embracing industrial FDM 3D printing services is no longer an alternative—it’s a competitive advantage. It’s your blueprint for building a more resilient and responsive manufacturing strategy.

Frequently Asked Questions (FAQs)

Q1: How does the strength of an FDM part compare to an injection-molded part?

A1: This is a nuanced question. Injection-molded parts are isotropic, meaning they have uniform strength in all directions. FDM parts can be anisotropic, with layer adhesion being a potential weakness. However, with industrial FDM, using the correct material (like Nylon or PC), optimal print orientation, and advanced slicer settings, the strength can be remarkably high and more than sufficient for a vast range of functional applications. For many uses, the difference is negligible.

Q2: Is the surface finish of FDM parts suitable for end-use consumer products?

A2: Straight off the printer, FDM parts have visible layer lines. However, a professional service like Yuesun3D offers a full suite of post-processing options. This can include sanding, priming, painting, vapor smoothing, and even electroplating. With these finishing techniques, you can achieve a high-quality, market-ready surface finish that rivals or even exceeds injection molding.

Q3: What is the true cost-benefit of FDM for production runs of 1,000 units compared to injection molding?

A3: For 1,000 units, FDM is often significantly more cost-effective when you factor in the total cost of ownership. With injection molding, you pay a high upfront cost for the mold (often $10,000+). With FDM, there is no mold cost. While the per-part cost of FDM is higher, the total cost for 1,000 units is typically lower with FDM because you avoid that massive initial investment. The “crossover point” where injection molding becomes cheaper is usually at several thousand units.

Q4: Can you use industrial FDM for parts that need to be UV resistant or used outdoors?

A4: Absolutely. Standard PLA is not suitable for outdoors, but engineering materials like ASA are specifically formulated for excellent UV resistance and weathering, making them perfect for automotive components, outdoor fixtures, and garden equipment. Material selection is key, and an expert partner can guide you.

Q5: We have a complex assembly. Can FDM help simplify it?

A5: Yes! This is one of the biggest advantages. FDM allows for part consolidation. You can design what was once an assembly of 10 different components into a single, stronger, more reliable printed part. This reduces assembly time, eliminates fasteners, lowers the risk of failure, and simplifies your supply chain.