How many times have you stared at a perfect 3D model on your screen, only to have your stomach drop when the first physical part arrives… and it doesn’t fit? That tiny miscalculation on screen becomes a giant, costly error in reality. What if you could eliminate that risk entirely? What if you could hold a functional, durable version of your design in your hands within days, test it in its actual environment, and make corrections before a single dollar is spent on expensive tooling? This isn’t a fantasy; it’s the everyday reality of using Fused Deposition Modeling for functional prototypes. Let’s explore why FDM is the ultimate tool for validating form, fit, and function, saving you from expensive mistakes and paving the way for a flawless product launch.

Beyond Looks: Why “Functional” is the Most Important Word in Prototyping

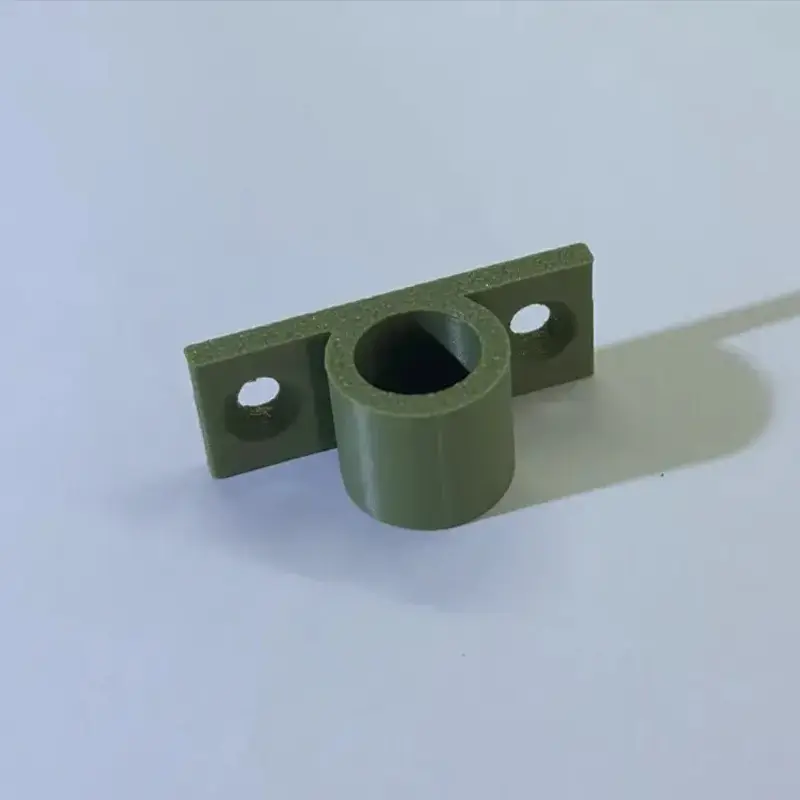

Many people think of a prototype as a visual aid—a 3D sketch. But if your prototype can’t withstand a little pressure, snap together with other components, or function as intended, what good is it? A truly functional prototype is a working model that behaves like the final product. It’s the difference between a cardboard mockup of a car and a drivable concept vehicle. Fused Deposition Modeling excels at creating these functional prototypes because it uses real, engineering-grade thermoplastics, not brittle, decorative resins. This means you can test more than just shape; you can test strength, durability, thermal resistance, and most critically—form and fit.

The FDM Advantage: More Than Just Plastic – It’s Functional Validation

So, what makes FDM so special for this critical stage of development? It boils down to two unbeatable advantages: material authenticity and blinding speed.

Real Materials, Real Performance: Engineering-Grade Thermoplastics

This is FDM’s superpower. Unlike other prototyping methods that use specialized, often weak materials, FDM builds parts from the same family of thermoplastics used in injection molding and other traditional manufacturing. Need a prototype that’s tough and durable? Print it in ABS. Need something with high heat resistance? Polycarbonate (PC) is your answer. What about a part that needs to be strong and slightly flexible? Nylon can do that. This material versatility means your prototype isn’t just a placeholder; it’s a high-fidelity, functional unit that gives you accurate feedback on how the final product will perform. When you test for form and fit, you’re testing with a material that closely mimics the end-result.

Speed That Fuels Innovation: Iterate in Days, Not Weeks

Time is the currency of innovation. The traditional cycle of design -> send out for quotes -> wait weeks for a machined prototype -> discover a flaw -> repeat is a massive drain on momentum. FDM compresses this timeline dramatically. With a professional service like Yuesun3D, you can go from a CAD file to a part in your hand in as little as 3-5 days. This speed enables an agile, iterative process. Find an interference in an assembly? Modify the CAD file at 3 PM, and a new, corrected version can be printing by 4 PM. This rapid iteration cycle allows you to explore more design options, catch more errors, and arrive at a better, more refined product in a fraction of the time.

The Form & Fit Imperative: Catching Costly Errors Before Production

Form and fit testing is the ultimate reality check. It’s where theoretical designs meet physical laws.

Case Study: Saving Thousands with a $50 FDM Prototype

Imagine a team designing a new electronic device. They have a custom heatsink and enclosure designed. Everything looks perfect in the assembly software. Instead of machining the aluminum heatsink and plastic enclosure (a cost of several thousand dollars), they first print the enclosure in high-temperature ABS using FDM. Upon assembly, they discover the mounting bosses for the heatsink are 0.5mm too tall, preventing a flush fit and compromising thermal transfer. This error, caught with a low-volume prototype service costing a few dozen dollars, saved them from a costly manufacturing mistake and a potential product failure. This is the power of a tangible test.

The Assembly Test: Your Final Exam Before Mass Production

The most critical form and fit test is the full assembly. Can all the parts you’ve designed actually come together smoothly? FDM prototypes are perfect for this. You can print every single component of your assembly at once, in the right materials, and physically put them together. You’ll identify issues like insufficient clearance for screws, misaligned snap-fits, or parts that are simply too difficult to assemble on a production line. Solving these problems at the prototype stage is cheap and easy. Solving them after injection molds are cut is a financial nightmare.

Integrating FDM Prototyping into Your Product Development Workflow

Making FDM prototyping a core part of your process is simple:

- Design Freeze (Initial): Complete your initial CAD model.

- FDM Prototype: Order functional prototypes of critical components or full assemblies.

- Form, Fit, Function Test: Physically test the parts. Assemble them. Stress them. Do they work?

- Iterate: Based on feedback, make quick CAD adjustments.

- Re-Print & Re-Test: Validate the changes with a new prototype round.

- Final Design Freeze: Once all tests pass, confidently move to mass production.

This workflow de-risks your entire project.

The Yuesun3D Difference: Professional-Grade FDM for Demanding Prototypes

Not all FDM is created equal. While desktop printers are great for hobbies, professional functional prototype testing requires industrial-grade equipment and expertise. Yuesun3D uses advanced FDM systems that offer superior accuracy (±0.1mm tolerances), repeatability, and can handle a wider range of engineering materials. Their focus on quality ensures your prototypes are accurate representations of your design, not just approximations. Furthermore, their engineering team can provide valuable Design for Manufacturability (DFM) feedback during the prototyping phase, suggesting improvements that will make the part not only better for prototyping but also more cost-effective for eventual mass production.

Conclusion: Don’t Guess, Test. The Power of Tactile Feedback.

In the race to market, skipping thorough form and fit validation is the riskiest shortcut you can take. Fused Deposition Modeling for functional prototypes provides the most direct path from digital idea to physical certainty. It transforms the abstract into the tangible, allowing you to see, feel, and test your design in the real world. It replaces expensive assumptions with cheap, rapid validation. In product development, what you don’t know can hurt you. With FDM prototyping, you can know everything before you commit. Stop guessing and start testing.

Frequently Asked Questions (FAQs)

Q1: How accurate are FDM prototypes for form and fit testing?

A1: Professionally printed FDM prototypes are highly accurate, typically holding tolerances of ±0.1mm. This is more than sufficient for the vast majority of form and fit testing applications. For critical features, the digital model can be adjusted to account for any predictable deviations, ensuring a perfect fit.

Q2: Can FDM prototypes really be used for functional testing, like stress or thermal tests?

A2> Absolutely. This is a key advantage. By choosing the right material (e.g., Nylon for strength, PC for heat resistance), FDM prototypes can undergo significant functional testing. While they may not have the exact same properties as a final production material (like molded fiberglass or metal), they provide invaluable data on how a design will perform under real-world conditions, far surpassing what any computer simulation can reliably predict.

Q3: Is it cost-effective to make multiple design iterations with FDM?

A3: Yes, this is one of its biggest financial benefits. Because there are no tooling costs, the cost of iteration is very low. You are essentially just paying for the material and machine time of each new version. Finding and fixing a problem in the second or third $100 prototype is infinitely cheaper than discovering it after a $10,000 mold has been created.

Q4: What is the best file format to provide for an FDM prototyping quote?

A4: The best format is a STEP file (.step or .stp) as it contains the most precise geometrical data. STL files are also very commonly used and are perfectly acceptable. The key is to provide a clean, “watertight” 3D model without errors.

Q5: We need a smooth surface finish for customer presentations. Can FDM provide that?

A5> Straight off the printer, FDM parts have visible layer lines. However, professional services like Yuesun3D offer post-processing options including sanding, priming, and painting that can achieve a very smooth, high-quality finish suitable for marketing samples and customer presentations, while still retaining the part’s functional integrity.