So, you’re at the manufacturing crossroads. You have a brilliant design ready to become a reality, and you’re faced with a classic dilemma: 3D Print CNC? It’s the “pick your weapon” moment of product development, and choosing wrong can cost you time, money, and a whole lot of frustration. But what if the choice was clear? What if you had a simple, logical framework to decide which technology truly serves your project best? This isn’t about one technology being better than the other; it’s about understanding which one is better for you. Let’s cut through the noise and dive into the five key scenarios where 3D printing doesn’t just compete with CNC machining—it wins, unequivocally.

The Manufacturing Crossroads: Two Paths, One Perfect Choice

Imagine manufacturing is a journey. CNC machining is like a master sculptor with a block of marble. Through incredible skill and precision, they carve away everything that isn’t the masterpiece. It’s a subtractive process, and it’s fantastic for what it does. 3D printing, or additive manufacturing, is like a potter building a complex vase layer by layer, coiling clay into intricate shapes that would be impossible to carve from a solid block. One takes away; the other adds. This fundamental philosophical difference—subtractive vs. additive—is the root of every decision you’ll make. Your project’s specific “DNA”—its geometry, volume, budget, and timeline—will determine which path leads to success.

The Fundamental Difference: Additive vs. Subtractive Philosophy

To make the right choice, you need to internalize this core distinction. CNC machining is a subtractive process. It starts with a solid block of material (metal, plastic, etc.), and uses sharp, rotating tools to meticulously cut away material until the desired part remains. It’s incredible for achieving ultra-tight tolerances and flawless surface finishes on parts that are mostly blocky or prismatic. 3D printing is an additive process. It starts with nothing and builds the part layer by layer, fusing material (plastic, resin, or metal powder) only where it’s needed, based on a digital 3D model. This is where its superpower lies: it thrives on complexity without compounding cost.

5 Key Scenarios Where 3D Printing Beats CNC Machining

Based on this additive advantage, here are the five situations where 3D printing is not just a good option, but the objectively superior choice.

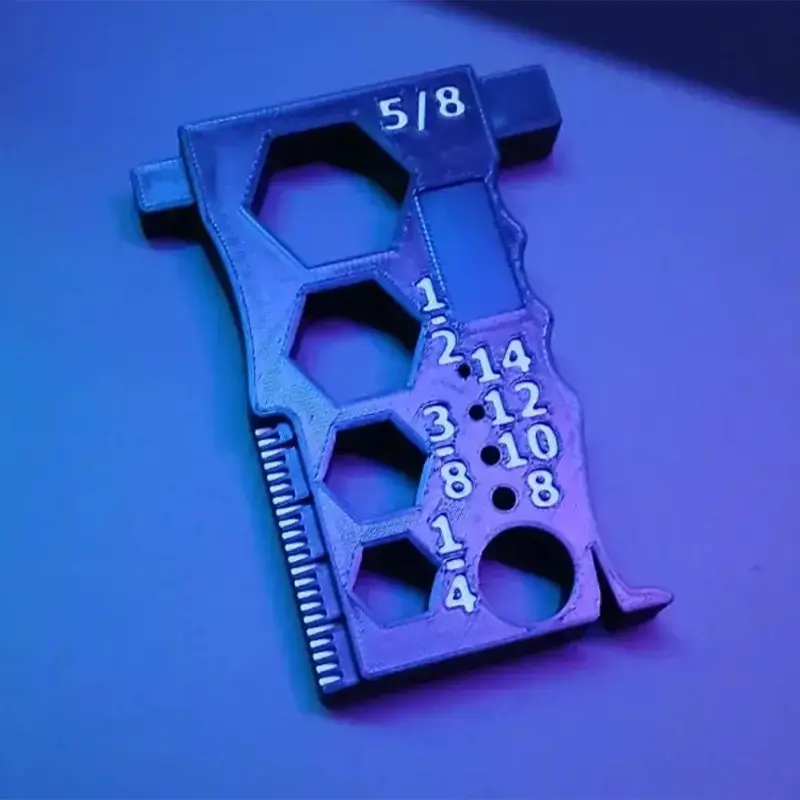

1. Conquering Complexity: Internal Geometries & Organic Shapes

This is 3D printing’s knockout punch. If your part has complex internal channels, undercuts, lattices, or organic, topology-optimized shapes inspired by nature (think bone structures), CNC machining struggles immensely. Machining these features often requires complex, expensive fixtures and multiple setups, dramatically increasing cost and time. For 3D printing, complexity is free. It builds these features as easily as it builds a simple cube. Think of internal cooling channels in a mold, lightweight aerospace brackets, or custom medical implants—all are perfect candidates for additive manufacturing.

2. The Speed of Innovation: Rapid Prototyping & Iteration

Speed isn’t just about how fast the machine runs; it’s about how fast you can innovate. If you’re in the prototyping phase and need to validate form, fit, and function, 3D printing is unbeatable. You can go from a CAD file to a part in your hand in as little as 24 hours. Found a flaw? Modify the digital file and print a new version the next day. CNC machining requires programming toolpaths, designing and building fixtures, and sourcing a solid block of material. For rapid iteration and agile development, the speed and flexibility of rapid prototyping services are undeniable.

3. The Economics of Low Volume: No Tooling, Lower Costs

Let’s talk money. CNC machining has a high upfront cost: the time to program the machine and, often, the cost of custom fixtures. For a one-off part or a small batch, this setup cost is amortized over very few units, making the per-part cost high. 3D printing has virtually no setup cost. The cost of printing one part is almost the same as the cost of printing ten. There are no fixtures, and the “tooling” is the digital file. For low-volume production, custom jigs, fixtures, or end-use parts (sub-500 units), 3D printing is almost always far more cost-effective.

4. Lightweighting & Part Consolidation: Designing Smarter

3D printing allows you to design parts that are both stronger and lighter. You can create internal lattice structures that remove weight without sacrificing strength. Furthermore, you can use additive manufacturing to consolidate what was an assembly of multiple CNC-machined parts into a single, stronger, more reliable printed part. This reduces assembly time, eliminates fasteners, and improves overall performance. It’s a fundamental redesign made possible by the technology.

5. Material Flexibility: Beyond Metals to Advanced Polymers

While CNC is largely limited to metals and harder plastics, industrial 3D printing offers a vast world of material properties. Need a part that is flexible, rubber-like, and impact-absorbing? TPU material has you covered. Need a high-temperature, chemical-resistant component? Certain nylons or PEKK are perfect. Need a material that is biocompatible for medical applications? There’s a resin for that. This ability to select a material based on its properties, not just its machinability, is a huge advantage.

The Inevitable Compromise: When CNC is Still the Right Choice

For balance, it’s crucial to know when CNC still reigns supreme. Choose CNC when:

- You Need Extreme Precision & Surface Finish: CNC can achieve tighter tolerances and smoother finishes straight off the machine.

- Your Parts are Simple & Blocky: If it’s essentially a cube with a few holes, CNC will be faster and cheaper at high volumes.

- You Require Specific Material Properties: If you absolutely need a solid block of 6061 aluminum or 316 stainless steel for structural reasons, CNC is your answer.

- Volume is Very High: For runs in the many thousands, injection molding becomes cheapest, but CNC is often used for the mold tools themselves.

The Yuesun3D Advantage: Guidance for Your Perfect Manufacturing Match

This decision doesn’t have to be yours alone. This is the value of a manufacturing partner like Yuesun3D. Their expertise isn’t in pushing one technology over the other; it’s in providing the optimal solution for your project. They can analyze your design, budget, and goals and provide a clear, unbiased recommendation. With expertise in both high-precision CNC and industrial 3D printing, they offer true guidance, ensuring you never pay for a process that doesn’t serve your ultimate purpose.

Conclusion: Let Your Project’s DNA Decide

The choice between 3D Print CNC isn’t a battle; it’s a selection process. By asking a few simple questions—Is it complex? Is it a prototype? What’s the volume?—you can guide yourself to the right answer. Embrace 3D printing for its unparalleled ability to handle complexity, speed up innovation, and make low-volume production economically viable. And remember, the best manufacturers don’t just offer a service; they offer the wisdom to choose the right path. Don’t force a technology onto your project; let your project’s DNA guide the technology.

Frequently Asked Questions (FAQs)

Q1: Can 3D printed parts be as strong as CNC machined parts?

A1> It depends on the material and technology. CNC parts are solid and isotropic (equally strong in all directions), which is great for metals. 3D printed parts can be very strong, but their strength can be directional (anisotropic), with layer adhesion being a potential weakness. However, with advanced materials like carbon-fiber filled Nylon and proper print orientation, 3D printed parts can achieve exceptional strength for many functional applications.

Q2: Which is more accurate, 3D printing or CNC?

A2> Generally, CNC machining holds tighter tolerances (e.g., ±0.025mm) and offers superior surface finishes straight from the machine. Industrial 3D printing can achieve excellent accuracy (e.g., ±0.05mm to ±0.1mm), but often requires post-processing to achieve a surface finish comparable to CNC.

Q3> I need a part that has both simple and complex features. What should I do?

A3> Consider hybrid manufacturing! This is where the two technologies are used together. For example, you could 3D print the complex, organic-shaped core of a part and then use CNC machining to machine precision mating surfaces, holes, or threads onto it, giving you the best of both worlds.

Q4: Is 3D printing really cheaper for one-off parts?

A4> In the vast majority of cases, yes. CNC machining requires significant setup time and programming, and you pay for the entire block of material you start with, most of which becomes waste. With 3D printing, you only pay for the material you use and the time it takes to print, with minimal setup, making it highly cost-effective for single parts and low volumes.

Q5: Can you help me decide which process to use for my specific project?

A5> Absolutely. This is a core service for a expert manufacturer like Yuesun3D. You can send them your CAD file, and their engineering team will provide a free design analysis and recommend the most efficient and cost-effective manufacturing process for your needs, whether it’s 3D printing, CNC, or a combination of both.